|

|||

|

|

|||

|

Page Title:

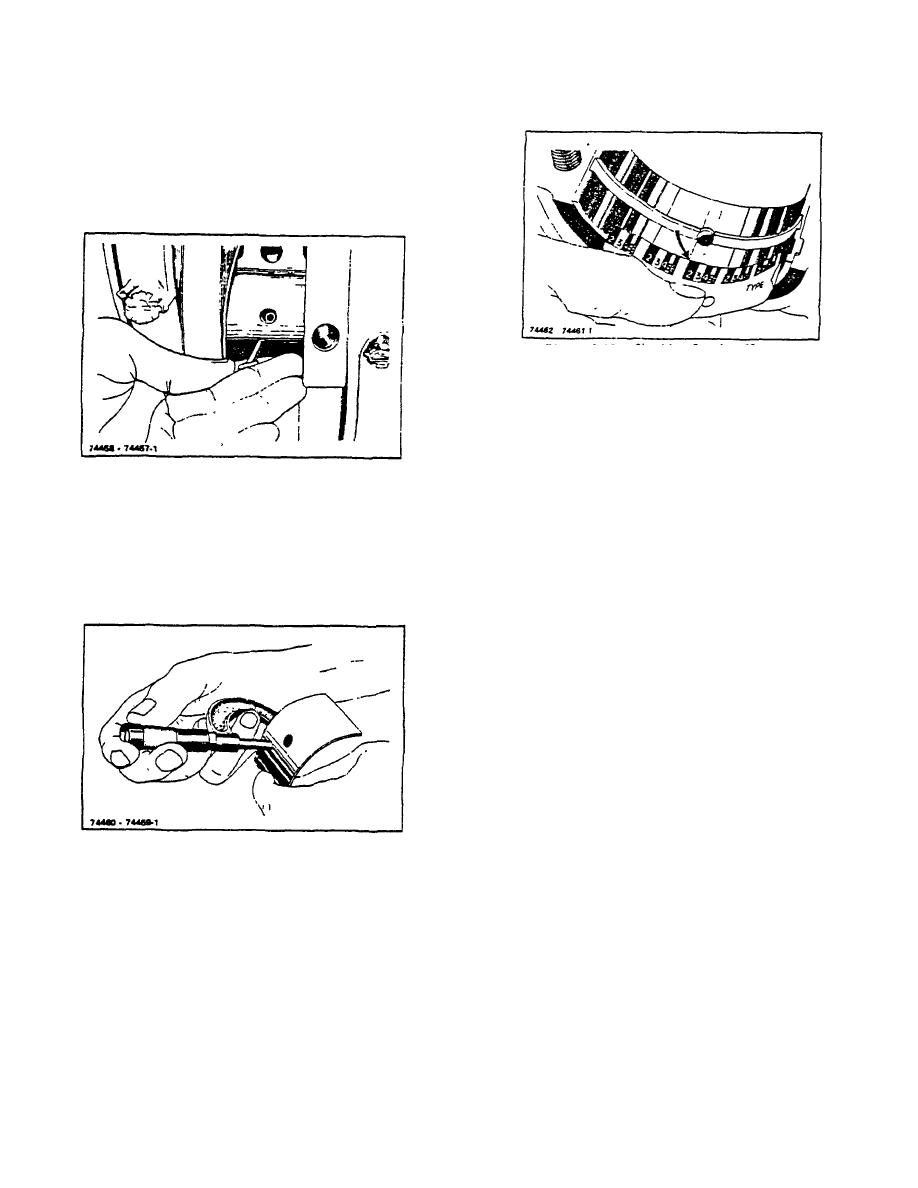

Figure 6-8. Removing Upper Half of Main Bearing Shell |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

most parts houses, which is a pin with an angular

head (Figure 6-8). This tool may be inserted in the oil

hole of the crankshaft and, as the crankshaft is turned

in a clockwise direction, the head of the pin picks up

the bearing shell and forces it out of the bore in the

block.

Figure 5-10. Checking Bearing Clearance with

Plastigauge

CAUTION

When using this method 00 NOT

TURN the crankshaft, as that would

destroy the Plastigauge.

Figure 6-8. Removing Upper Half of Main Bearing Shell

By placing the Plastigauge in the bearing and

The thickness of the bearing shells is given in TOPIC

tightening it in place, the width of the Plastigauge

1. FITS AND TOLERANCES. If this thickness has

after crushing determines the bearing clearance, as

been reduced more than .0005" beyond the

shown in Figure 6-10.

maximum allowable tolerance the bearing shell must

be replaced (Figure 6-8).

The term "crush" is generally understood as the

projection of the bearing edges above flush with the

mating surfaces of the nearing seat and cap. This

crushing action forces the bearing halves into close

contact with their seats for greater rigidity and good

heat conduction.

The correct amount of crush has been allowed during

the manufacture of the bearings, and so attention to

that detail is necessary at the time of replacement.

The use of a torque wrench for tightening bearings is

necessary to insure sufficient "crush" on the bearings,

to force the shells against the crankcase metal

without distortion.

An alternative method (Figure 6-11) is to use a piece

Figure 6-9. Measuring Bearing Thickness

of 1/2" feeler stock lengthwise in the bearing shell, on

a film of oil. The thickness of the feeler stock should

If visual inspection of the crankshaft has shown no

be equivalent to the maximum clearance permissible

indication of excessive wear or scoring, the clearance

in the bearing.

of the bearings should be checked with feeler stock.

Assemble the bearing cap and tighten the screws,

Check each bearing, one at a time, by using a piece

torquing them to specification, then try to turn the

of Plastigauge of a diameter specified to check

crankshaft by hand to determine whether or not a

certain clearances.

drag is felt.

If a definite drag is felt and the piece of feeler stock is

equivalent to, but

R-104-1

3-19

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |