|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

TOPIC 5. CYLINDER HEAD

A. DESCRIPTION

The cylinder head is an alloy cast iron unit, secured to

the engine block with special hardened studs and

capscrews. The head seals the top end of the cylinders

to form the combustion chambers and passages for the

intake of the air-fuel mixture, and the expulsion of

exhaust gases, as well as cored passages through

which the coolant flows to prevent overheating.

B. REMOVAL

1. Drain water from block by opening water drain

cock.

2. Drain radiator.

3. Loosen clamps on upper radiator hose and

remove hose, taking care not to damage

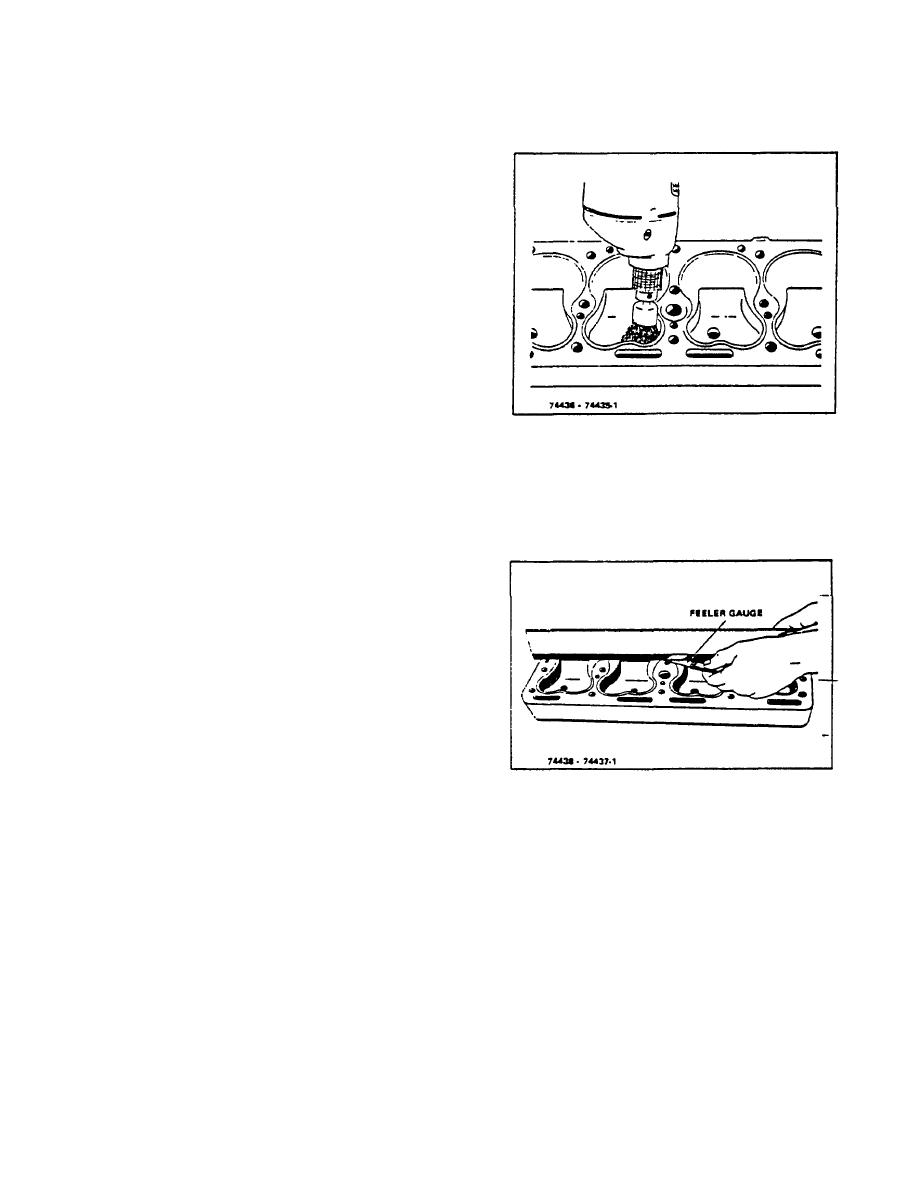

Figure 5-1. Cleaning Carbon from Combustion Chamber

thermostat located at cylinder head end of hose.

4. Disconnect water bypass tube from water pump.

3. Make sure that gasket contact surfaces on the

5. Disconnect wire from water temperature sender.

head are clean, smooth and flat.

6. Disconnect spark plug ignition cables from spark

4. Inspect cylinder head for cracks, holes and

plugs, and identify each cable.

warpage. Replace damaged heads.

7. Remove spark plugs, and cap or tape exposed

ports.

8. Remove capscrew or nut holding distributor

clamp to cylinder head. Remove distributor 9.

Refer to TOPIC 3 and remove the manifold.

10. Remove cylinder head mounting capscrews and

stud nuts.

11. Lift the cylinder head and gasket off the engine

and place it on a work bench.

12. With a clean, dry cloth wipe all exposed engine

internal areas free of water and place a

protective cover, such as a plastic sheet, over

exposed cylinders.

C. SERVICING

Figure 5-2. Checking Cylinder Head Flatness

1. Using a scraper and wire brush, remove all

Lengthwise

carbon from combustion areas. See Figure 5-1.

2. Clean the cylinder head thoroughly Figure 5-1.

5. Check out-of-flatness with straight edge and

Cleaning Carbon from Combustion Chamber

feeler gauge: maximum permissible is .00075"

with an acceptable cleaning solvent and dry

per inch of width or length (Figures 5-2 and 5-3).

thoroughly with compressed air.

Thus, for a cylinder head 16" long, maximum

permissible lengthwise out-of-flatness is .012".

Out-of-flatness should vary gradually and

uniformly from end to end and side to side.

Localized depressions or high spots should not

exceed .003".

R-104-1

3-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |