|

|||

|

|

|||

|

Page Title:

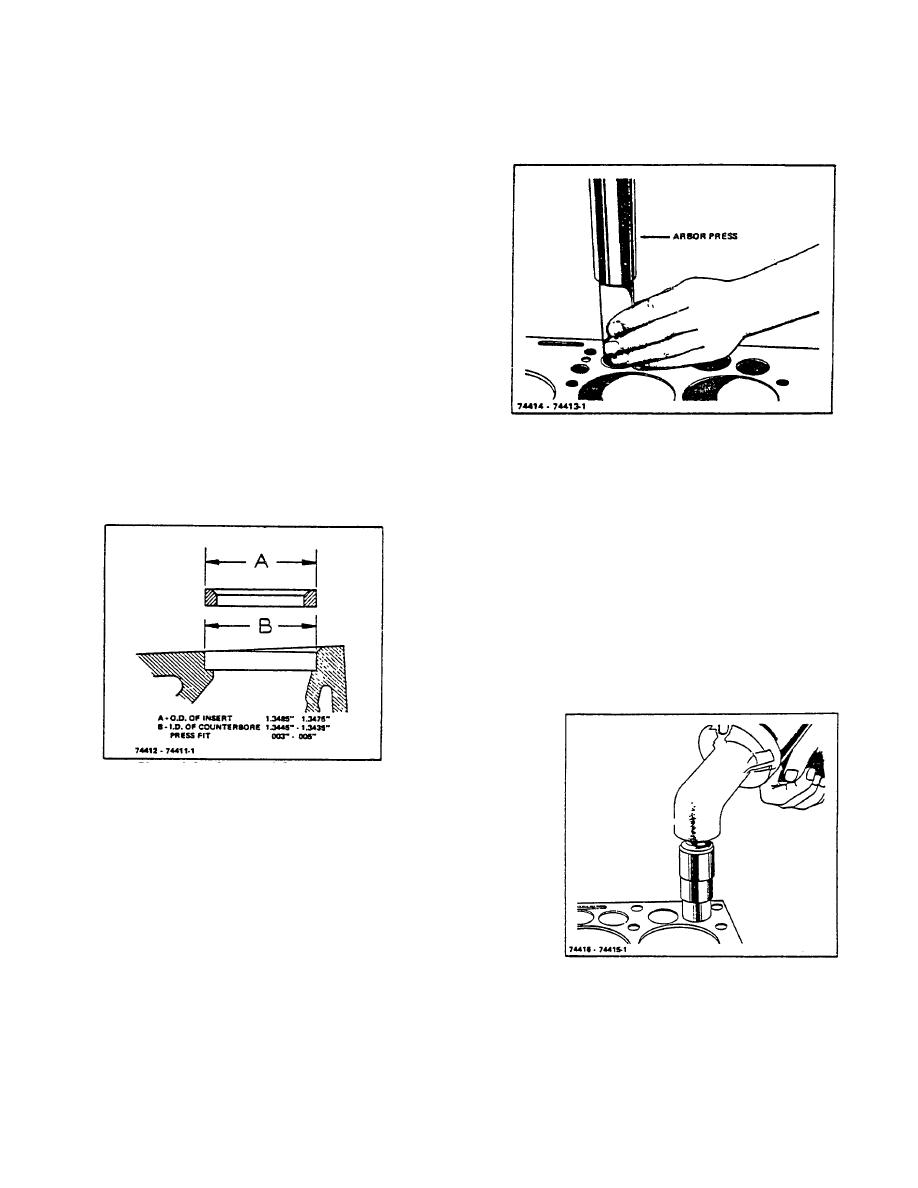

Figure 4-5. Insert and Counterbore Dimensions |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

Inspect all exhaust valve inserts in the block and

assures that the insert is seated firmly on the

replace any that are loose, cracked or otherwise

bottom of the counterbore.

damaged. Use puller for removing faulty insert

as shown in Figure 4-4.

When required to replace with new insert, clean

and counterbore for .010" larger insert using

counterbore tool with correct fitting pilot.

When machining the counterbore, be sure to go

deep enough with the tool to clean up the

bottom; so that, the insert will have full contact to

carry away the heat.

It is not recommended to install new inserts

having the same outside diameter as the one

removed. Refer to Dimensions of Standard

Inserts and Counterbores shown in Figure 4-5.

A - O.D. of Insert ................ 1.3485"-1.3475"

Figure 4-6. Installing Valve Seat Insert with an Arbor

B - I.D. of

Press

Counterbore .................. 1.3445"-1.3435"

Press Fit .............................. .003"-.005"

3. Valve Seat Grinding

Grind the Intake and exhaust valve seats in the

block (Figure 4-7) in accordance with specified

dimensions in TOPIC 1.

FITS AND

TOLERANCES. Before removing the arbor,

indicate the seat. Total Indicator reading of the

run-out must not be more than .002". Use a pilot

having a solid stem with a long taper, as all

valve seats must be ground concentric and

square with either new or worn valve stem guide

holes (Figure 4-8).

Figure 4-5. Insert and Counterbore Dimensions

When OVERSIZE inserts are used, dimensions

of the insert and counterbore increase

proportionately .010" to .020" depending on the

oversize.

New insert installation should have a press fit.

Chill Insert in container with dry ice for 20

minutes before assembling.

Insert may then be installed in the counterbore

Figure 4-7. Grinding Valve Seat

using a piloted driver, tapping in place with very

light hammer blows, without the possibility of

shearing the side walls (Figure 4-6).

This

R-104-1

3-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |