|

|||

|

|

|||

|

Page Title:

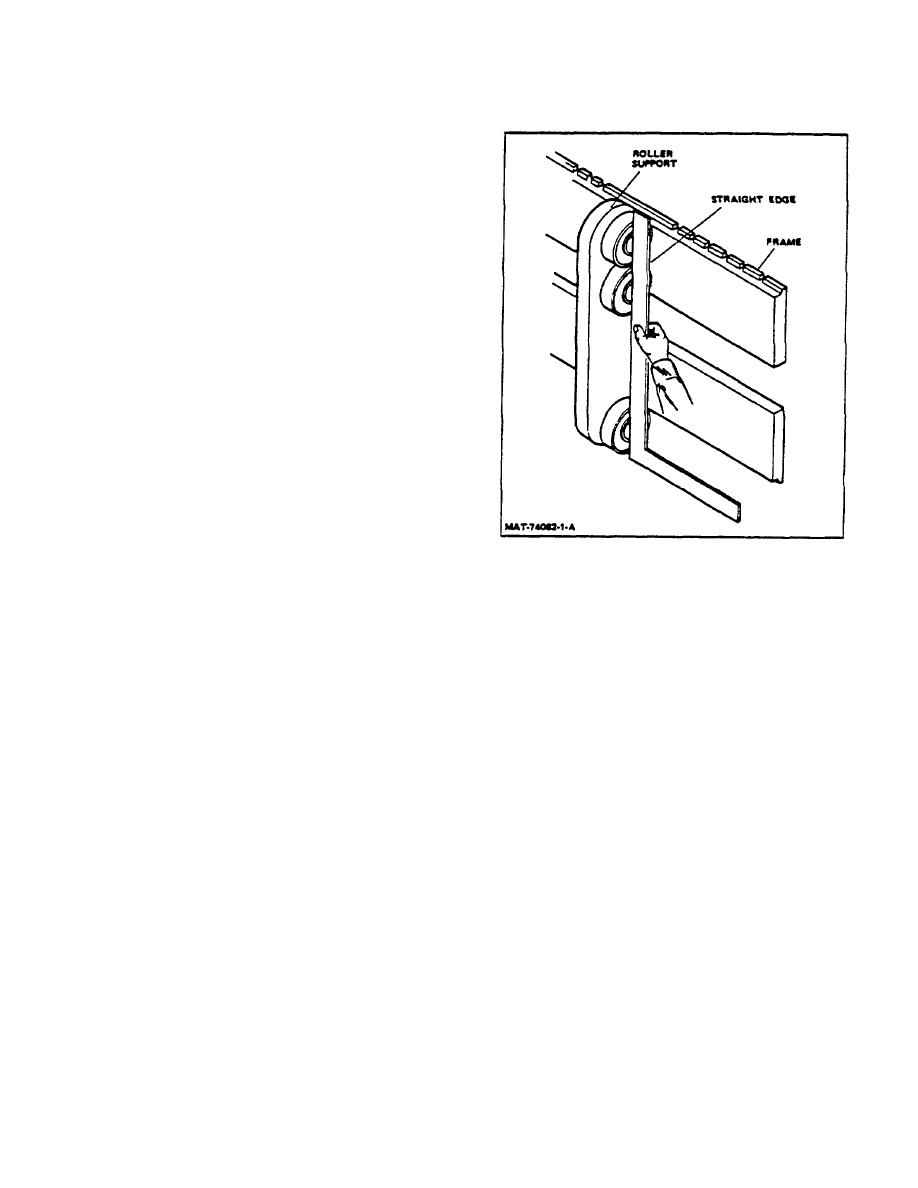

Figure 3. Checking Bearing Alignment |

|

||

| ||||||||||

|

|

TM 10-3930-644-14&P

1. Place two pieces of wood, approximately 2"

thick, underneath forks (or attachments), (one

towards front of the forks and one underneath

carriage frame.

2. Remove carriage stop capscrews (or stop, if

applicable).

3. Remove lift chain anchor pins (or connecting

link, if applicable), and disconnect chains from

carriage.

4. Ensure that no attachments secure the carriage

to the mast. Start engine and raise inner mast

high enough to clear inner mast uprights.

5. Back lift truck out of the way and move carriage

to desired location.

NOTE

If carriage is of the canted bearing

design, it must be adjusted before

installation.

Refer to following

PARAGRAPH C, ADJUSTMENT.

C. ADJUSTMENT-CANTED BEARING TYPE (Figure 1)

Figure 3. Checking Bearing Alignment

1. Use an inside spanning tool and check inside of

web of inner mast assembly and determine

D.

INSTALLATION (EXTRA-LIFT AND HIGH FREE

narrowest point where bearings contact inner

LIFT 3,5000 14,000 lb AND ALL TRI-MAX)

mast uprights.

1. Raise inner mast high enough to clear carriage

2. Set outside spanning tool to match inside

assembly bearings.

spanning tool. Lock tool in position.

2. Position lift truck so that inner mast uprights are

3. Install bearings on roller studs on carriage.

directly centered over carriage bearings. Slowly

Span bearings on carriage assembly at the

lower inner mast making sure carriage bearings

maximum camber point with outside spanning

slide into inner mast uprights.

tool. Span all sets of bearings. Shim bearings

to produce maximum .015 inch clearance with

3. Reinstall carriage stop capscrews (or stop, if

spanning tool.

applicable).

4. To check bearing alignment, place a

4. Reinstall lift chain anchor pins (or connecting

straightedge against stud centerline to all

link, if applicable), and reinstall lift chains.

bearings on both sides of carriage assembly.

No visible gap should be seen between bearings

and the straightedge (Fig 3).

2-102

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |