|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-644-14&P

6. Tighten the contact assembly locking screw.

7. Install dust seal, rotor and cap.

8. Start engine and recheck dwell reading on

meter.

Needle should now hold steady at

specified dwell angle. If so, remove dwell meter

and remove remote switch.

If not, repeat

procedure starting with item 4 above.

I. STATIC IGNITION TIMING

The exact timing of the spark depends on the actual

breakage, or opening, of the electrical contact across the

points. Should there be any question as to the accuracy

of point setting relative to the engine timing mark, the

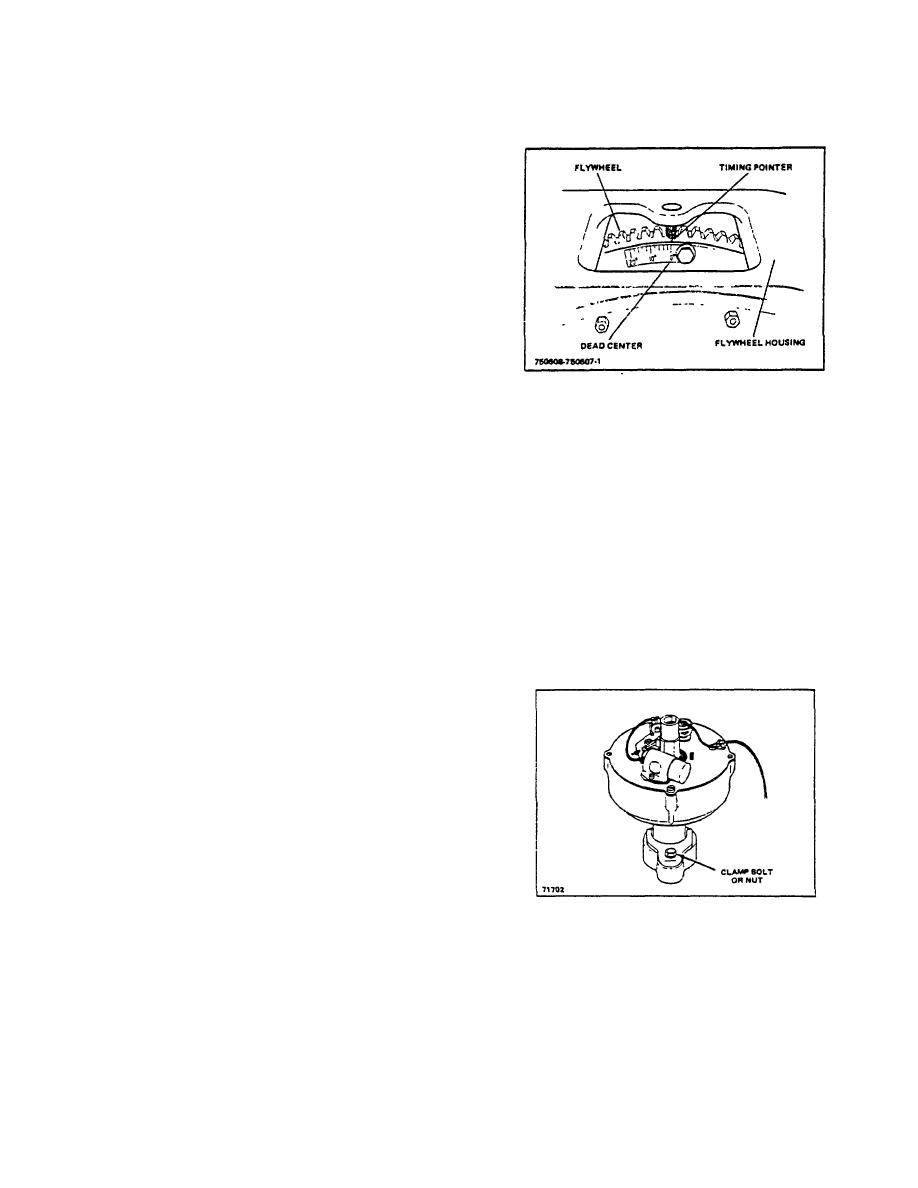

Figure 5-5. Flywheel Timing Marks

use of one of the following methods is recommended.

goes out, turn back to the original position and

1. Make up a simple light circuit consisting of an

repeat the procedure.

automotive light bulb with soldered on lead: or a

10.

When you have located the distributor in the

socket with lead wires attached.

proper position (with test lamp out) tighten

2. Remove distributor cap, rotor and dust seal.

distributor hold down clamp.

Ensure that distributor point gap is properly set.

11.

With the test lamp still connected, check for

See specifications for distributor.

proper setting by releasing tension on rotor.

3. Loosen distributor clamp (Figure 5-6).

a. With rotor held against rotation, light

4. Remove timing window cover on flywheel

should go out.

housing and remove the spark plug from number

b. With rotor released, test lamp should be

one cylinder.

on.

5. Place thumb over spark plug opening and rotate

12.

Remove test lamp. Replac e dust seal, rotor and

engine crankshaft by hand until outward

distributor cap.

pressure against thumb is felt. Continue turning

13.

Install spark plug.

crankshaft until D.C. mark (Figure 5-5) is aligned

with timing pointer at center of timing window.

6. Clip one lead to positive, or ungrounded, side of

the battery. Attach the other lead to the primary

wire connection on the side of the distributor

(Type I) or the distributor coil negative terminal

(Type II).

7. hold rotor against rotation. Rotate distributor

slowly in the direction of rotation until test lamp

just lights. Now start the adjustment.

8. Very slowly turn the distributor housing against

the direction of shaft rotation until the test lamp

goes out. Stop immediately. Do not pass this

point or turn the Distributor housing back and

forth to locate it.

9. Should you turn the housing too fast or too far

Figure 5-6. Distributor Timing adjustment (Typical)

beyond the point where the light

M-104-1

2-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |