| |

TM 10-3930-643-34

GENERAL SUPPORT PROPELLER AND PROPELLER SHAFTS MAINTENANCE. (cont)

16-1.

Front Differential Carrier Assembly.

ASSEMBLY (cont)

82.

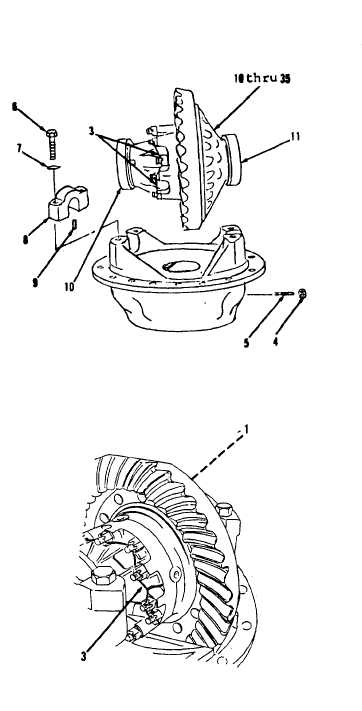

Install cups (11 and 10) on

differential assembly.

83.

Using hoist and sling, position

items 10 thru 35 as an assembly to

carrier (51).

84.

Install two adjustment rings (2).

Hand turn against cups (11 and 10).

85.

Install two pins (9), bearing caps

(8), four washers (7) and bolts (6).

Tighten bolts (6) to 160 to 190 lb-ft

torque.

Identification marks on

bearing caps and carrier must be

alined during installation. If

bearing caps do not seat properly,

check adjustment rings (2) for cross

threading.

86.

Using a 15/16” socket and socket

wrench handle, install screw (5) and

nut (4).

NOTE

The following is a difference

between M10A Forklift models.

87.

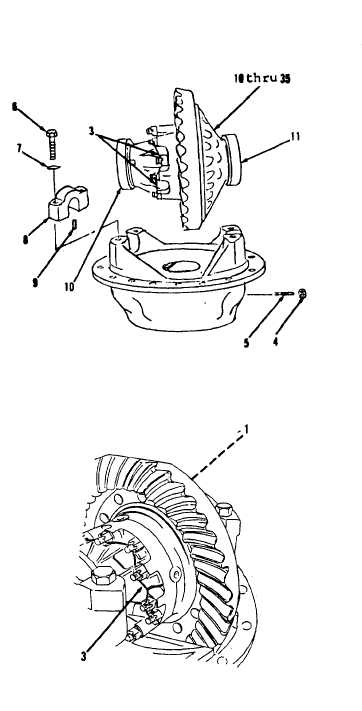

Using long round nose pliers, install

cotter pin (1) and on vehicles S/N

2000 and below and 2904 and above,

install two new lockwires (3).

ADJUSTMENT

88.

Refer to paragraph 16-3 for

differential assembly adjustment

procedures.

NOTE

Return M10A Forklift to original

equipment condition.

(Sheet 13 of 13)

GO to sheet 14

END OF TASK

16-14

|