| |

ENGINE, FUEL, EXHAUST AND COOLING

4-4.

Cylinder Head Assembly with

DISASSEMBLY/CLEANING/INSPECTION

27.

28.

29.

30.

31.

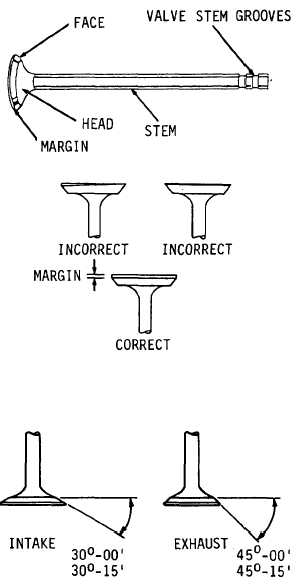

Check valve stem ends. If

grind ends square.

TM 10-3930-643-34

TROUBLESHOOTING AND MAINTENANCE.

Valves. (Sheet 9 of 18)

worn,

Resurface valve face angle, if

necessary.

Maintain valve face

margin, as shown.

A minimum margin

must be maintained of 0.088 inches

for intake valves-large head (14) and

0.045 inches for exhaust valves-small

head (13).

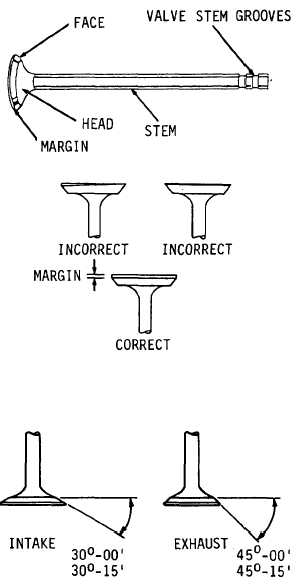

Maintain valve face angles, as shown.

Valve must be replaced if more than

0.008 inches of stock is removed or

margin falls

below

minimum

specification in Step 31.

After resurfacing, check valve face

runout with dial indicator.

NOTE

Valve must be replaced if total

indicator reading is greater than

0.002 inches.

Check valve face contact with

Prussian blue.

Bluing should appear

around entire contact

surface of

valve face and valve seat.

If bluing

does not appear around entire contact

surface, angles do not match.

Valve

seats must be resurfaced.

Go to sheet 10

4-37

|