| |

TM 10-3930-643-34

GENERAL SUPPORT ENGINE, FUEL, EXHAUST AND COOLING MAINTENANCE.

13-14.

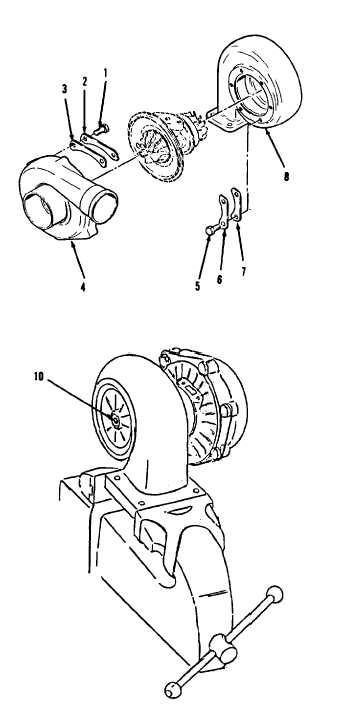

Turbocharger. (Sheet 10 of 10)

ASSEMBLY

52.

53.

54.

55.

56.

57.

58.

59.

NOTE

Aline punch marks on turbine

housing and center housing and

well as on compressor housing and

center

housing

during

installation.

Install turbine housing (8).

Coat bolt threads with anti-seize

compound. Using a 1/2” socket and

torque wrench, install three clamps

(7), lockplates (6) and six bolts

(5).

Tighten bolts (5) to 100 to 130

in-lb.

Bend tabs on lockplate (6) to secure

bolts (5).

Install compressor housing (4).

Using a 1/2” socket and socket wrench

handle, install three clamp plates

(3), lockplates (2) and six bolts

(l).

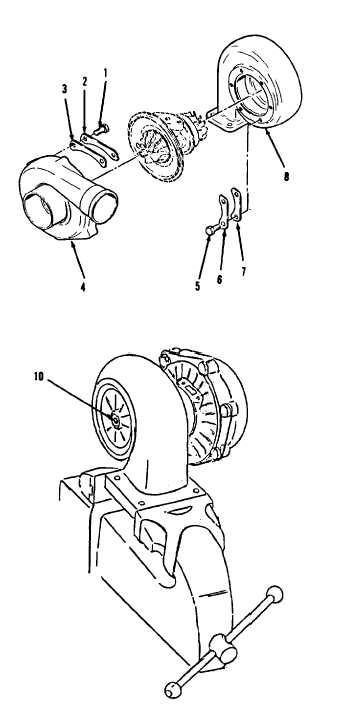

Push wheel assembly (10) shaft as far

as possible from turbine end.

Rotate wheel assembly (10) shaft and

check for binding.

Wheel assembly

(10) shaft must rotate freely without

interference.

Push as far as

possible from compressor end.

Rotate wheel assembly (10) shaft and

check for binding.

NOTE

. If turbocharger is not

to be

installed immediately, lubricate

internally and install protec-

tive covers on all openings.

. Return M10A Forklift to original

equipment condition.

END OF TASK

13-95

|