| |

TM 10-3930-643-34

GENERAL SUPPORT ENGINE, FUEL, EXHAUST AND COOLING MAINTENANCE. (cont)

13-14.

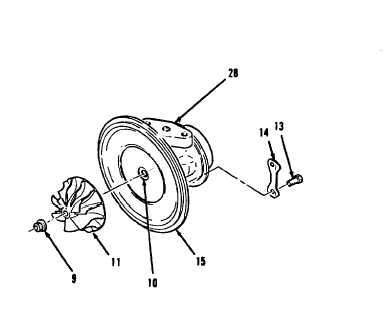

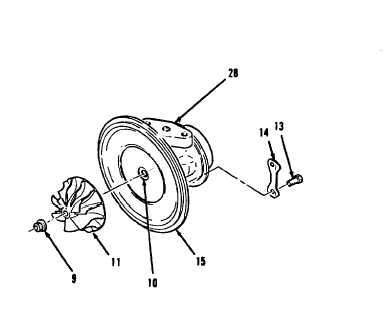

Turbocharger. (Sheet 9 of 10)

ASSEMBLY (cont)

NOTE

Aline punch marks on

center housing.

Use

damage seal ring.

installation, engage

backplate and

care not to

To ease

open side of

43.

44.

45.

46.

47.

48.

49.

50.

-

-

-

seal ring in backplate bore first.

Install new seal ring (16) on

compressor side of

center

housing

(28).

Using a flat brass punch, install

spring (19) in backplate (15).

Install backplate (15) over shaft of

wheel assembly (10) and thrust collar

(17) in center housing (28).

Install lockplates (14) and four

bolts (13) in center housing (28).

Bend tabs on lockplate (14) to secure

four bolts (13).

Install impeller (11),

Lubricate threads of wheel assembly

(10) shaft and contact face of

locknut (9) with clean engine oil.

Install new locknut (9), finger

tight.

NOTE

Place center housing in soft-

jawed vise. Clamp on hex-end of

turbine wheel.

51.

Using a 9/16” socket and torque

wrench, tighten locknut (9) to 18 to

20 lb-ft. Tighten an additional 1/4

turn after reaching specification.

Go to sheet 10

13-94

|