| |

GENERAL SUPPORT

13-8.

Pistons,

TM 10-3930-643-34

ENGINE, FUEL, EXHAUST AND COOLING MAINTENANCE.

Connecting Rods and Connecting Rod Bearings. (Sheet 7 of 12)

CLEANING/INSPECTION

14•

Inspect piston (5) for scuffed or

scored skirts, cracked or worn piston

lands.

Check pin bore for wear and

cracks, replace if necessary.

15.

Using a feeler gage, measure running

clearance between piston (5) and

cylinder sleeve, replace piston

(5)

if necessary.

Measure piston (5) at

a 90 degree angle from the piston pin

(10).

Clearance should be between

0.0045 and 0.0075 inches, refer to

paragraph 13-3.

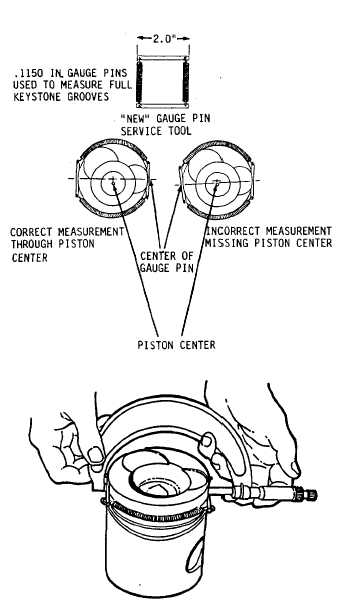

NOTE

Full keystone grooves use the

0.1150 inch gage pins to determine

piston ring groove wear. Be sure

that the center of the gage

pins

aline with the center of

the

piston so that gage pins are

parallel. Rectangular grooves do

not use gage pins.

Use side

clearance

and ring gap to

determine piston ring groove wear.

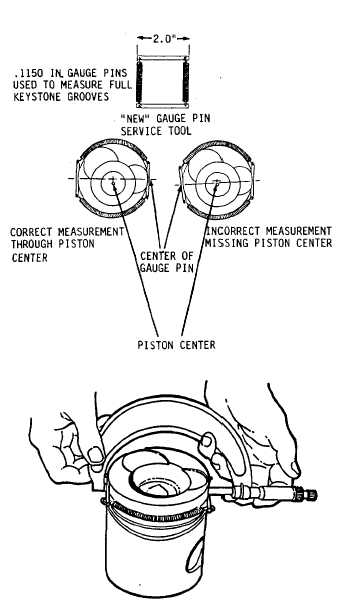

16.

17.

18.

19.

Install tool 3020 in the top of

piston (5) ring groove.

Using 4-5 inch micrometer, measure

piston (5)

over gage pins, if

necessary.

Repeat steps

16 and 17 for

intermediate ring (7) and ring (8).

For ring (7), upper limit is 4.3168

inches and replacement limit is

4.2844 inches. For ring (8), side

clearance must be between 0.002 and

0.004 inches.

Remove tool 3020 from piston (5) ring

groove.

Go to sheet 8

13-55

|