| |

TM 10-3930-643-34

GENERAL SUPPORT ENGINE, FUEL, EXHAUST AND COOLING MAINTENANCE. (cont)

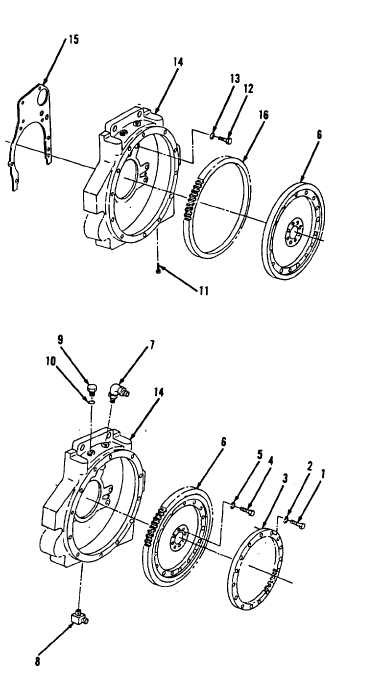

13-7.

Flywheel and Housing. (Sheet 5 of 5)

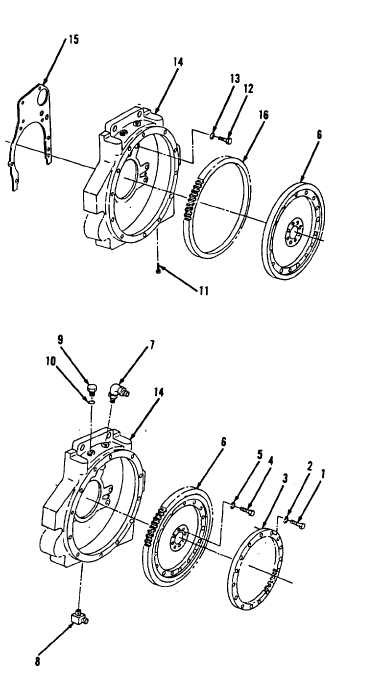

INSTALLATION

10.

11.

12.

13.

14.

15.

16.

Heat gear

and place

(16) to 500-550 degrees F

on flywheel (6) while hot.

NOTE

Install wear sleeve and oil seal,

paragraph 13-6.

Position new gasket (15) and flywheel

housing (14) in front of crankcase

with hoist and sling.

Using a 3/4” socket and torque

wrench, install new gasket (15),

flywheel housing (14), eight washers

(13) and bolts (12). Tighten eight

bolts (12) to 105 lb-ft.

Install four bolts (11).

Install new gasket (10), plug (9) and

elbows (8 and 7) in flywheel housing

(14).

Install flywheel (6), eight washers

(5) and bolts (4).

Tighten eight

bolts (4) to 125 lb-ft.

Eight bolts

(4) must be tightened evenly to draw

flywheel (6) onto crankshaft evenly.

Remove hoist and sling.

Using a 3/4” socket and socket wrench

handle, install gear (3), 16 washers

(2) and bolts (1) on flywheel (6).

NOTE

Return M10A Forklift to original

equipment condition.

END OF TASK

13-48

|