| |

TM 10-3930-643-34

GENERAL MAINTENANCE PROCEDURES.

2-13.

Electrical Repairs.

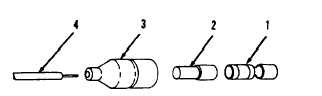

(7) Connector, terminal-type, weather-proof.

DISASSEMBLY

1.

Slide shell (3) back to expose sleeve (2).

2.

Slide sleeve (2) back to expose terminal (1).

3.

Remove and discard terminal (1).

4.

Remove sleeve (2) and shell (3).

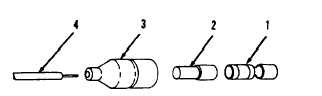

ASSEMBLY

1.

2.

3.

4.

5.

6.

7.

Strip wire (4), refer to Wire Size Chart. Do not nick or cut strands.

Tin bare wires. Use resin-core solder to coat bare wires.

If using

solid core solder, clean wires

Slide shell (3) and sleeve (2)

New terminal must be selected to

at the terminal connection. New

with flux before tinning.

onto wire (4).

NOTE

match the size of the mating contact

terminal must also match the crimping

area with the thickness of the wire.

Strip wire (4), refer to Wire Size Chart. Do not nick or cut strands.

Tin bare wires. Use resin-core solder to coat bare wires.

If using

solid core solder, clean wires with flux before tinning.

Insert wire (4) into new terminal (1).

NOTE

Connector sleeve and shell are held in position over terminal by

compression. Sleeve must be firmly seated on terminal and shell must

be firmly seated over sleeve.

Slide shell (3) over sleeve (2) and terminal (1).

2-23

|