| |

TM 10-3930-643-34

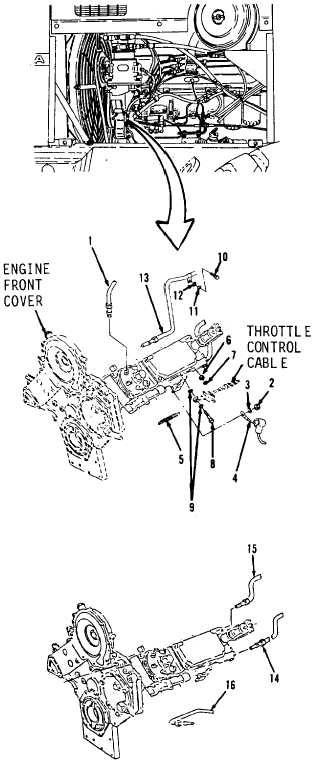

ENGINE, FUEL, EXHAUST AND COOLING

4-14.

Fuel Injection Pump, Cover

REMOVAL

Before performing injection

TROUBLESHOOTING

Plate, Adapter

AND MAINTENANCE. (cont)

and Drive Gears. (Sheet 2 of 9)

pump

removal procedure, rotate engine

clockwise until the No. 1 piston

is on compression

stroke

and

timing pointer is at 15 degrees

BTDC plus or minus 1 degree.

If the pump is to be reinstalled,

DO NOT rotate the pump drive shaft

after the pump has been removed.

Thoroughly clean left side of

engine to prevent dirt from

entering pump.

Be sure to plug all

openings of pump and lines to

prevent entry of dirt.

Failure to observe the preceding

can result in severe damage to

engine or fuel injection pump.

NOTE

Tag all hose and tube assemblies

before disconnecting to aid in

installation.

1.

Using a

3/4“

open

end

wrench,

disconnect six fuel injector lines

(1) from right side of engine.

3*

Using a flat tip screwdriver, remove

nut (2), washer (3) and terminal (4).

3.

Using long round nose pliers, a 7/16”

socket and a 7/16” open end

wrench,

remove spring (5), nut (6), washer

(7), bolt (8) and two washers (9).

4.

Using a 9/16” socket and socket

wrench handle, remove bolt (10), lock

washer (11) and washer (12).

Leave

clip attached to tube assembly (13).

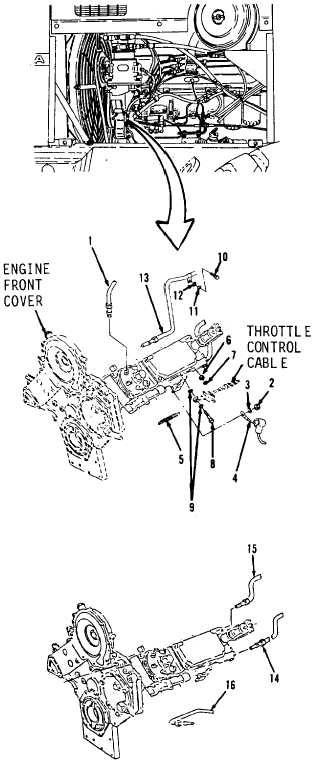

5.

Using a 3/4” open end wrench,

disconnect tube assemblies (13, 14,

15 and 16).

Go to sheet 3

4-94

|