| |

TM 10-3930-643-34

ENGINE, FUEL, EXHAUST AND

4-6.

Rocker Arm Assembly

ADJUSTMENT

COOLING TROUBLESHOOTING

and Valve Cover. (Sheet

28.

Using a flat tip screwdriver, a 9/16”

open end wrench and a feeler gage,

adjust rocker arm numbers 1, 2, 3, 6,

7 and 10 in top of engine, refer to

Valve Lash Adjustment Chart.

29.

Turn crankshaft on bottom, rear of

engine until No. 6 piston is at TDC

(compression) which is one complete

revolution of vibration damper,

30.

Adjust rocker arm numbers 4, 5, 8, 9,

11 and 12, refer to Valve Lash

Adjustment Chart.

31.

Using a flat tip screwdriver, a 9/16”

open end wrench and a feeler gage,

tighten 12 nuts (26) to 20 lb-ft.

NOTE

If valve are in correct adjustment,

proceed to installation.

INSTALLATION

32.

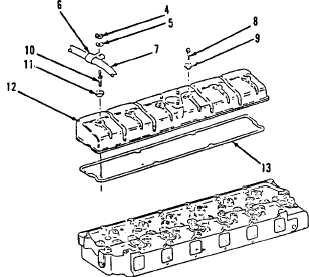

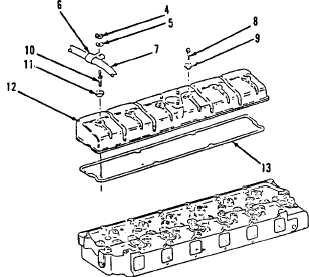

Using a 1/2” socket and socket wrench

handle, install new gasket (13),

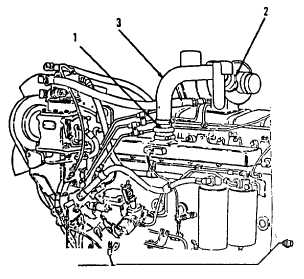

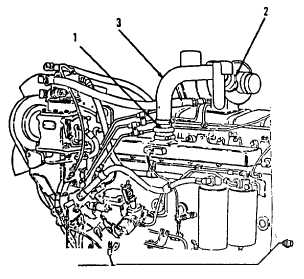

access cover (12), new preformed

packing (11), stud (10), five new

preformed packing (9) and bolts (8).

Tighten bolts (8) and stud (10) to 26

lb-ft.

33.

Position hose assembly (7) and using

a 1/2” socket and socket wrench

handle, install clamp (6), washer (5)

and nut (4).

34.

Install tube assembly (3).

35.

Using a flat tip screwdriver, tighten

clamps (2 and 1).

NOTE

AND MAINTENANCE.

9 of 9)

Return M10A Forklift to original END OF TASK

equipment condition.

4-59

|