| |

TM 10-3930-638-24&P

4-3. FUEL SYSTEM MAINTENANCE (cont)

b. Fuel Injection Pump (cont).

STEP

LOCATION

INSPECTION (cont)

19

20

ITEM

Transfer

a. Blades

EXAMINE FOR

X

X

X

pump

(104)

b. Liner

X

(103)

Governor

a. Pivot

X

shaft

(60)

b. Arm (56) X

X

X

X

X

X

X

X

X

X

X

X

SPECIFICALLY

INSPECT

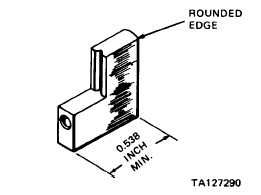

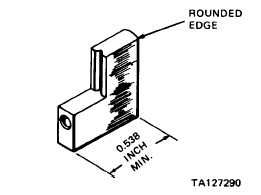

Check for chipping on all

edges, including spring

bore edges for pitting, im-

bedded foreign particles

or scoring on rounded’

edges. Determine blade

wear by measuring length

(0.538 inch minimum).

Inspect flat surfaces visual-

ly for deep scores (see il-

lustration). If any dis-

crepancies are noted, re-

place blade sets and spring

Inside diameter in low pres-

sure area for wear

Chipped or worn knife edge

Points of contact with thrust

sleeve and pivot shaft for

excessive wear

4-112

|