| |

TM 10-3930-638-24&P

4-3. FUEL SYSTEM MAINTENANCE (cont)

a. Fuel Injector (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

CLEANING AND INSPECTION (cont)

22

Adjusting screw

Inspect

Replace if worn, or if threads damaged

(4, 9)

23

Spring (5)

Inspect

Check that free length of spring is 0.563

inch and compressed length is 0.456 to

0.478 inch at 29 pounds

RECONDITIONING/OVERHAUL

24

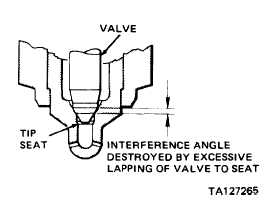

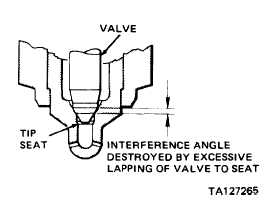

CAUTION

Excessive lapping will destroy interference angle between seat and

valve causing loss of chatter with poor atomization resulting in

replacement of fuel injector.

Injector body

Lap valve and

Use lapping compound FSCM 05083 P/N

(11) tip seat

tip seat

66-0145. Place small amount of lapping

compound on valve seat and insert valve

in injector body. Grip top of valve with

valve retractor P/N 66-0148 and rotate

valve by hand, first clockwise then coun-

terclockwise for a total of 3 to 5 revolu-

tions. Flush injector body thoroughly;

wash valve and reassemble injector and re-

test. If valve and seat are worn, seat may

be tight, but chatter may have been lost in

the lapping process. In such an instance

replace fuel injector

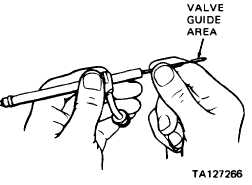

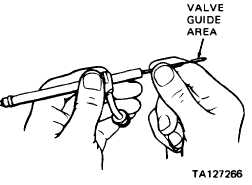

25

Injector body

Lap valve

Use lapping compound FSCM 05083 P/N

(11) valve guide

guide

66-0145. Place small amount on guide area

of valve. Bottom valve in body and grasp

with valve retractor P/N 66-0148. Rotate

valve 10 revolutions while raising and low-

ering it very slightly. Flush and wash com-

pound from both parts, assemble fuel in-

jector and recheck fuel leak-off. If leak-off

is still low, lap guide until correct leak-off

is obtained. Flush fuel injector thoroughly

after lapping

4-84

|