| |

TM 10-3930-638-24&P

4-3. FUEL SYSTEM MAINTENANCE (cont)

a. Fuel Injector (cont).

Injector leak-off

check

STEP

LOCATION

ITEM

ACTION

REMARKS

TESTING (cont)

d. Check for pitted or eroded valve or

(cont)

seat, valve interference angle worn,

bent valve and distorted body. These

conditions require replacement of

complete fuel injector

6

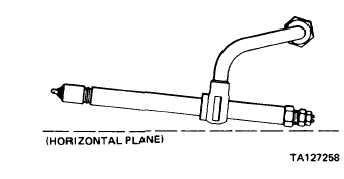

a. Loosen connector

nuts and reposition

injector tip slightly

above horizontal

plane

b. Tighten con-

nector nuts

and raise

pressure to

1500 PSI

c. Observe

After one drop falls, leak-off must be 3 to

leakage

10 drops in 30 seconds with No. 2 diesel

from

fuel at room temperature (65 to 75

return

degrees)

end of

fuel injector

If proper leak-off is not obtained:

a. If leak-off is excessive, replace fuel

injector

b. If leak-off is low, disassemble and

clean fuel injector (see disassembly)

c. Lap valve to guide area to increase

leak-off (see reconditioning)

DISASSEMBLY

NOTE

Fuel injector contains precision ground and lap fitted parts;

exercise care in keeping your work area and tools clean. Handle

parts carefully to avoid damaging them.

7

Carbon dam

Remove

Use long nose pliers

seal (1)

4-80

|