| |

TM 10-3930-638-24&P

4-2. ENGINE MAINTENANCE (cont)

f. Pistons and Connecting Rods (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

CLEANING (cont)

WARNING

Wear safety glasses when drying parts with compressed air, Fail-

ure to do so could cause serious injury to eyes and possible blind-

ness. If you hurt your eyes or if a foreign object is blown into

your eyes, seek medical attention immediately.

6

All parts

Clean

7

Piston (4)

a. Overall

Clean

b. Piston ring

Clean

groove

c. Piston oil hole

Clean

INSPECTION

8

Piston(4)

a. Overall

Inspect

b. Piston pin bore

Measure

diameter

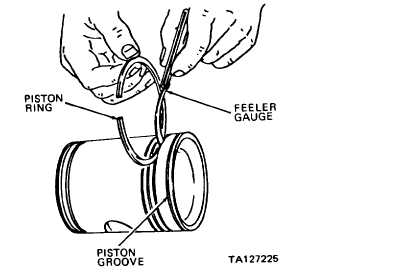

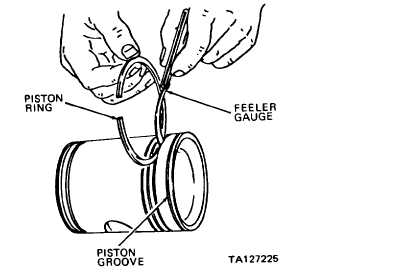

C. Oil ring side

Measure

clearance

Use cleaning solvent P-D-680. Dry thor-

oughly with moisture free compressed

air or clean cloth

Remove carbon from piston using care

not to scratch piston

Use groove cleaning tool

Use small drill or fine wire

Inspect for cracks, damage, scoring, evi-

dence of overheating and damaged ring

grooves. If any of these conditions ob-

served, replace piston

Use bore gage and measure two places,

90 degrees apart. Replace piston if dia-

meter is greater than 1.2508 inches

Use feeler gauage. If measurement exceed:

0.005 inch, replace piston

4-45

|