| |

TM 10-3930-638-24&P

4-2. ENGINE MAINTENANCE (cont)

d. Crankshaft and Main Bearings (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

INSTALLATION (cont)

5

(cont)

16

17

Connecting

Plasti gage

Position

rod bearing

cap and liner

(2)

Cylinder

a. Crankshaft (8)

Clean

block

connecting rod

journals

NOTE

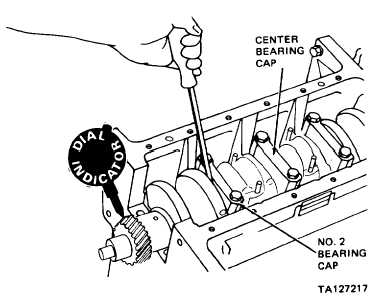

If end play is greater than this dimension,

replace center main bearing liners and

recheck end play. If end play is still

greater than 0.015 inch, replace crank-

shaft (8)

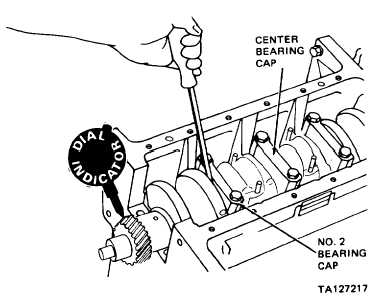

Clean bearing liner with clean, lintless

cloth; position plasti gage crosswise on

liner

Use clean, lintless cloth

Install connecting rod bearing caps in proper numbered position

with numbered side of cap towards camshaft.

b. Four connecting

Position

rod bearing

caps (2)

c. Eight connecting

Install and

Tighten to 45-50 pounds foot torque; then

rod nuts (1)

remove

remove

d. Four connecting

Remove

rod bearing

caps (2)

4-35

|