| |

TM 10-3930-638-24&P

3-29. HYDRAULIC LIFT SYSTEM TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2. LOAD DRIFTS DOWN

NOTE

After completion of each check, lower forks

until resting on ground. Then, turn engine

off.

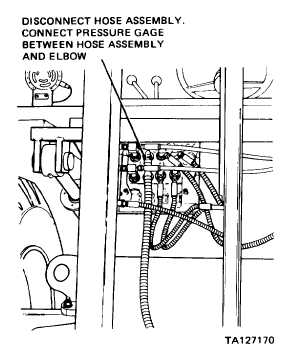

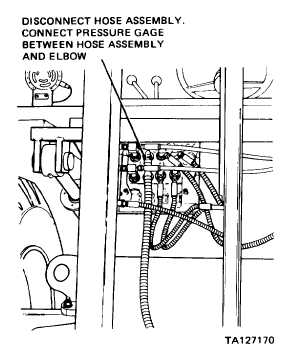

With engine off, operate control levers several times to

relieve hydraulic pressure. Disconnect hose assembly

connected between control valve and lift cylinder

assembly at control valve (refer to illustration).

NOTE

Increase engine speed as necessary to prevent

engine stall.

Connect a 3000 PSI pressure gage between elbow on con

trol valve and hose assembly.

Start engine and place LIFT control lever in RAISE

position until mast assembly is at full height; continue

to hold lever in RAISE position until pressure gage

indicates 2500-2550 PSI with engine at full throttle.

With LIFT control lever in neutral position, observe

pressure gage and mast assembly.

a. If mast assembly drifts down and pressure gage indication does not decrease, remove and repair

lift cylinder assembly (para 3-30e).

b. If pressure gage indication decreases, replace or repair control valve (para 3-30a).

3. UNABLE TO SIDESHIFT LOAD (ALL OTHER FUNCTIONS NORMAL)

NOTE

After completion of each check, turn engine off.

Step 1.

Check sideshift cylinder assembly for hydraulic oil leakage.

a. If hydraulic oil leakage is observed, remove and repair sideshift cylinder assembly (para 3-30c).

b. If hydraulic oil leakage is not observed, proceed to step 2.

Step 2. Check hose assemblies between side shift cylinder assembly and control valve for hydraulic oil leakage.

a. If hydraulic oil leakage is observed at hose assemblies, replace leaking hose assembly (para 2-56 f).

b. If hydraulic oil leakage is not observed at hose assemblies, proceed to step 3.

3-197

|