| |

TM 10-3930-638-24&P

12-9. ENGINE TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4. ENGINE MISFIRES (cont)

Step 4. Check for loose fuel injector nozzle.

a. If a fuel injector nozzle is loose, tighten clamp.

b. If fuel injector nozzles are not loose proceed to step 5 below.

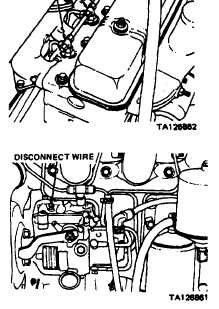

Step 5. Disconnect wire at fuel injection pump terminal.

With ignition switch in ON position, check for +24 Vdc between wire

and chassis ground.

a. If +24 Vdc is obtained, reconnect wire to terminal and crack (open)

a fuel injector line at fuel injector pump.

Crank engine and check if fuel is pumped through fuel injection

pump.

(1) If fuel is pumped through injection pump, notify

direct support maintenance.

(2) If fuel is not pumped through fuel injection

pump, replace it (notify direct support maintenance)

b. If +24 Vdc is not obtaned, troubleshoot electrical system

(para 2-19).

5. ENGINE STALLS FREQUENTLY OR DOES NOT DEVELOP FULL

POWER

WARNING

If NBC exposure is suspected, all air filter media

should be handled by personnel wearing protec-

tive equipment. Consult your unit NBC Officer

or NBC NCO for appropriate handling or dis-

posal procedure.

Step 1.

Check if air cleaner inidicator red flag is in view.

a. If in view, depress reset button on top of indicator and check that red flag dis-

appears from view. (If red flag does not disappear from view, replace air

cleaner indicator as described in para 2–15c.) Crank engine and check if red

flag is in view; if in view, service air cleaner (pars 2–15c).

b. If red flag is not in view. proceed to step 2 below.

2-18

Change 5

|