| |

TM 10-3930-638-24&P

2 - 9 . E N G I N E T R O U B L E S H O O T I N G ( c o n t )

1.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE HARD TO START OR WILL NOT START (cont)

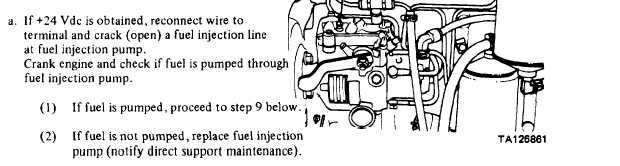

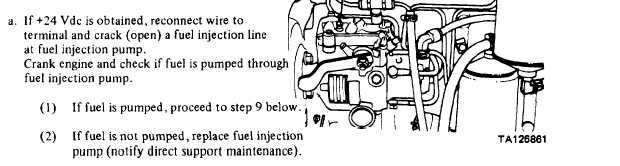

Step 8.

Disconnect wire at fuel injection pump terminal.

With ignition switch in ON position, check for +24

Vdc between wire and chassis ground.

b. If +24 Vdc is not obtained, troubleshoot electrical system (para 2-19).

Step 9. Check for incorrect or contaminated fuel in fuel tank (if contaminated, fuel will have a milky white

coloring).

a.

b.

If fuel is contaminated, drain fuel tank, clean and fill with correct fuel (para 2-15d (1) and

replace fuel filters (para 2- 15e and 2- 15f).

(Refer to current lubrication order for correct fuel.)

If fuel is not contaminated, proceed to step 10 below.

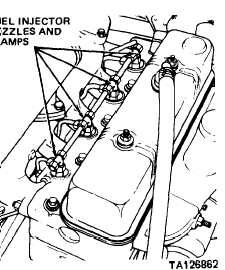

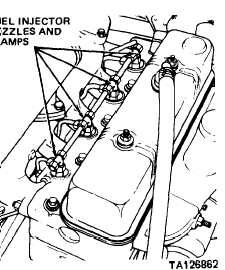

Step 10. Check for loose fuel injector nozzle.

a. If a fuel injector nozzle is loose, tighten clamp.

b. If fuel injector nozzles are not loose, proceed to

step 11 below.

Step 11. Check for damaged fuel injector nozzle seal or damaged nozzle (notify direct support maintenance).

a. If fuel injector nozzle seal or nozzle is damaged. replace (para 3-6b; notify direct support

maintenance).

b. 1 f fuel injector nozzle seal and nozzle check okay, proceed to step 12.

2-14

|