| |

TM 10-3930-638-24&P

2 - 9 . E N G I N E T R O U B L E S H O O T I N G ( c o n t)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. ENGINE HARD TO START OR WILL NOT START (cont)

Step 5. Check for leaks at fittings between fuel tank and fuel injection pump.

a. If leaks are observed, tighten or replace fittings (para 2-15d (2)).

b. If leaks are not observed, proceed to step 6 below.

Step 6.

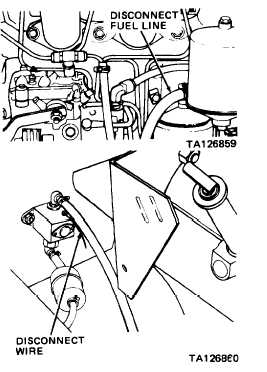

Disconnect fuel line at fuel filter head.

Place ignition switch in ON position and check if a

slight buzz can be heard at electric fuel pump and if

fuel is pumped out of disconnected line.

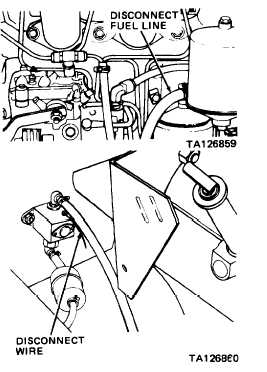

a. If slight buzz indicating electric fuel pump operation

is not heard, disconnect wire at terminal on electric

fuel pump and check for +24 Vdc between wire and

chassis ground.

(1) If +24 Vdc is not obtained, troubleshoot

electrical system (para 2-19).

(2) If +24 Vdc is obtained, replace electric

fuel pump (para 2-15b).

b. If fuel is not pumped out of disconnected fuel line,

remove lines and fittings between fuel tank and fuel

filter head and clean/replace lines, in-line fuel falter,

and/or fuel strainer (para 2-15).

c. If fuel is pumped out of disconnected fuel line, pro-

teed to step 7 below.

Step 7.

Check for clogged fuel filters by disconnecting fuel line between fuel filter head and fuel injection

pump at fuel injection pump.

Place ignition switch in ON position and crank engine.

Fuel should be pumped out of disconnected line.

a. If fuel is not pumped out of disconnected line, reconnect fuel line and service fuel filters (para

2-15e and 2-15 f).

b. If fuel is pumped out of disconnected line, reconnect fuel line and proceed to step 8 below.

2-13

|