| |

TM 10-3930-638-24&P

2-43. SERVICE BRAKE MAINTENANCE (cont)

a. Service Brake Assembly (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

INSPECTION

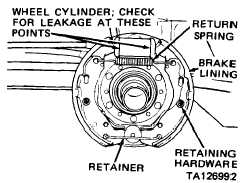

1 Front axle,

a. Shoe and linings (6)

Inspect for wear

Replace if worn to 3/32 inch or less; or

right side

and signs of over-

if contaminated by lubricant or brake

heating and

fluid

lubricant

contamination

CAUTION

Don’t depress brake pedal completely in following step; depress

pedal only enough to check that brake shoes expand.

b. Wheel cylinder (9)

Inspect for fluid

Replace if necessary

leakage at boots.

Depress brake

pedal and check

that brake shoes

expand. Release

brake pedal and

check that brake

shoes retract

NOTE

If brake shoes don’t expand or retract in the above step, this

indicates that wheel cylinder piston is sticking.

c. Retaining hardware

Inspect for missing Replace missing parts

parts

NOTE

If brake shoes, wheel cylinder, or retaining hardware are okay,

reinstall axle shaft and hub assembly (para 2-39f) and wheel

assembly and perform above procedures on remaining wheel and

axle. If brake shoes, wheel cylinder, or retaining hardware are

not okay or other problems are observed, proceed to step 2

below.

2-283

|