| |

TM 10-3930-638-24&P

2-34. WIRING HARNESS MAINTENANCE (cont)

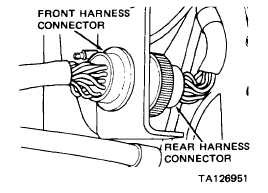

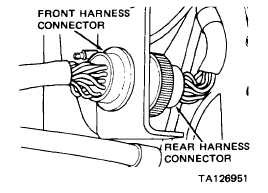

b. Rear Wiring Harness (cont).

STEP

LOCATION

ITEM

ACTION

REMARKS

INSPECTION (cent)

4

Harness connector

Disconnect and

Disconnect front harness connector (para

inspect

2-34a). Replace harness if connector is

defective (notify direct support

maintenance)

5

Other connectors and

Inspect

Replace bent, damaged or missing

terminals

terminals and connectors

REPAIR

6

Wiring harness and wires

Tape

Wrap insulating tape over frayed insulation

NOTE

Gage of replacement wire must be greater than or equal to

gage of defective wire.

7

Wiring harness and wires

Replace wire

If defective wire is accessible, cut a length

of same gage wire and splice using

insulated splice connector. If wire is not

accessible, replace wiring harness (refer

to direct support maintenance)

8

Replace

Cut wire close to defective terminal, strip

insulation to depth of terminal well, and

crimp wire to new terminal or connector

TESTING

NOTE

Testing of the rear wiring harness consists of starting the engine,

turning on all lights, depressing the service brake pedal, and

observing that all lights/indicators/gages are operating. If any

abnormal indications are observed, refer to the troubleshooting

procedures in this section. To perform a continuity test of the

rear wiring harness using an ohmmeter, refer to the electrical

system wiring schematic located in appendix F.

Wire terminals and

connectors

2-193

|