| |

TM 10-3930-638-24&P

2-21. STARTING SYSTEM TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. STARTER CRANKS TOO SLOWLY (cont)

Step 2. Remove starter assembly from engine (para

2-27a).

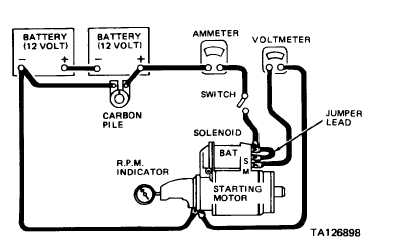

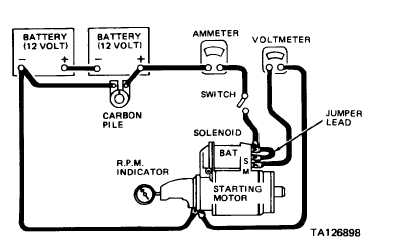

Connect no-load test setup to starter as

illustrated, and adjust carbon pile for 20 Vdc

indication on voltmeter.

a. If ammeter indicates

52 to 90 amperes

and rpm indicator

indicates 8000 to

13,000 rpm, discon-

nect starter from test

setup and reinstall

on engine (para

2-27a).

2.

b. If ammeter does not indicate 52 to 90 amperes, or rpm indicator does not indicate 8000 to

13,000 rpm, record voltage, current and rpm, and replace starter assembly (para 2-27a).

Forward test results to direct support maintenance with defective starter.

STARTER FAILS TO CRANK

Step 1.

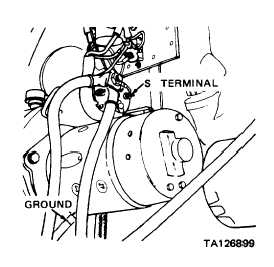

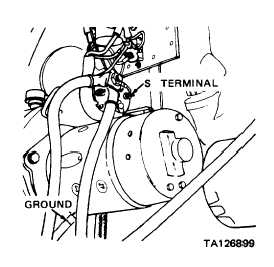

Connect voltmeter leads to S terminal of starter

solenoid and ground.

Note voltmeter indication while an assistant

depresses START switch.

a. If voltmeter indicates 24 Vdc, replace

starter assembly para 2-27a).

b. If voltmeter indicates less than 24 Vdc,

or zero, proceed to step 2.

2-101

|