| |

TM 10-3930-638-24&P

4-5. AXLE MAINTENANCE (cont)

a. Differential Carrier (cont).

ADJUSTMENTS (cont)

26

(cont)

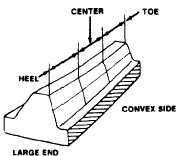

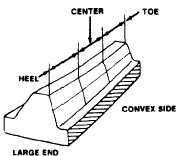

ALL CONTACT BEARINGS SHOWN BELOW ARE ON RIGHT HAND SPIRAL

RING GEAR – THE DRIVE IS ON THE CONVEX SIDE OF THE TOOTH.

CONDITION 1

TYPICAL PREFERRED BEARING ON BOTH SIDES OF TOOTH

WHILE UNDER A LIGHT LOAD

CONDITION 2

TOE BEARING ON BOTH SIDES OF TOOTH-GEAR SET NOISY. TO

MOVE BEARING TOWARD HEEL INCREASE BACKLASH WITHIN LIMITS

BY MOVING GEAR AWAY FROM PINION.

CONDITION 3

HEEL BEARING ON BOTH SIDES OF TOOTH-GEAR SET NOISY AND

COULD RESULT IN EARLY GEAR FAILURE. TO MOVE BEARING TO-

WARD TOE DECREASE BACKLASH WITHIN LIMITS BY MOVING GEAR

TOWARD PINION.

CONDITION 4

LOW BEARING ON GEAR AND HIGH BEARING ON PINION. CORRECT

BY PULLING PINION AWAY FROM GEAR. INCREASE MOUNTING DIS-

TANCE BY ADDING SHIMS BETWEEN BEARING CAGE AND DIFFERENTIAL

HOUSING.

CONDITION 5

HIGH BEARING ON GEAR AND LOW BEARING ON PINION, CORRECT

BY MOVING PINION IN TOWARD GEAR. DECREASE MOUNTING DIS-

TANCE BY REMOVING SHIMS FROM BETWEEN BEARING CAGE AND

DIFFERENTIAL HOUSING.

BACKLASH

BACKLASH SHOULD BE MEASURED WITH A DIAL INDICATOR

RIGIDLY MOUNTED WITH THE STEM PERPENDICULAR TO THE TOOTH

SURFACE AT THE EXTREME HEEL.

4-246

|