|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-638-24&P

4-2. ENGINE MAINTENANCE (cont)

i. Oil Pump (cont).

ITEM

STEP

LOCATION

ACTION

REMARKS

INSPECTION (cont)

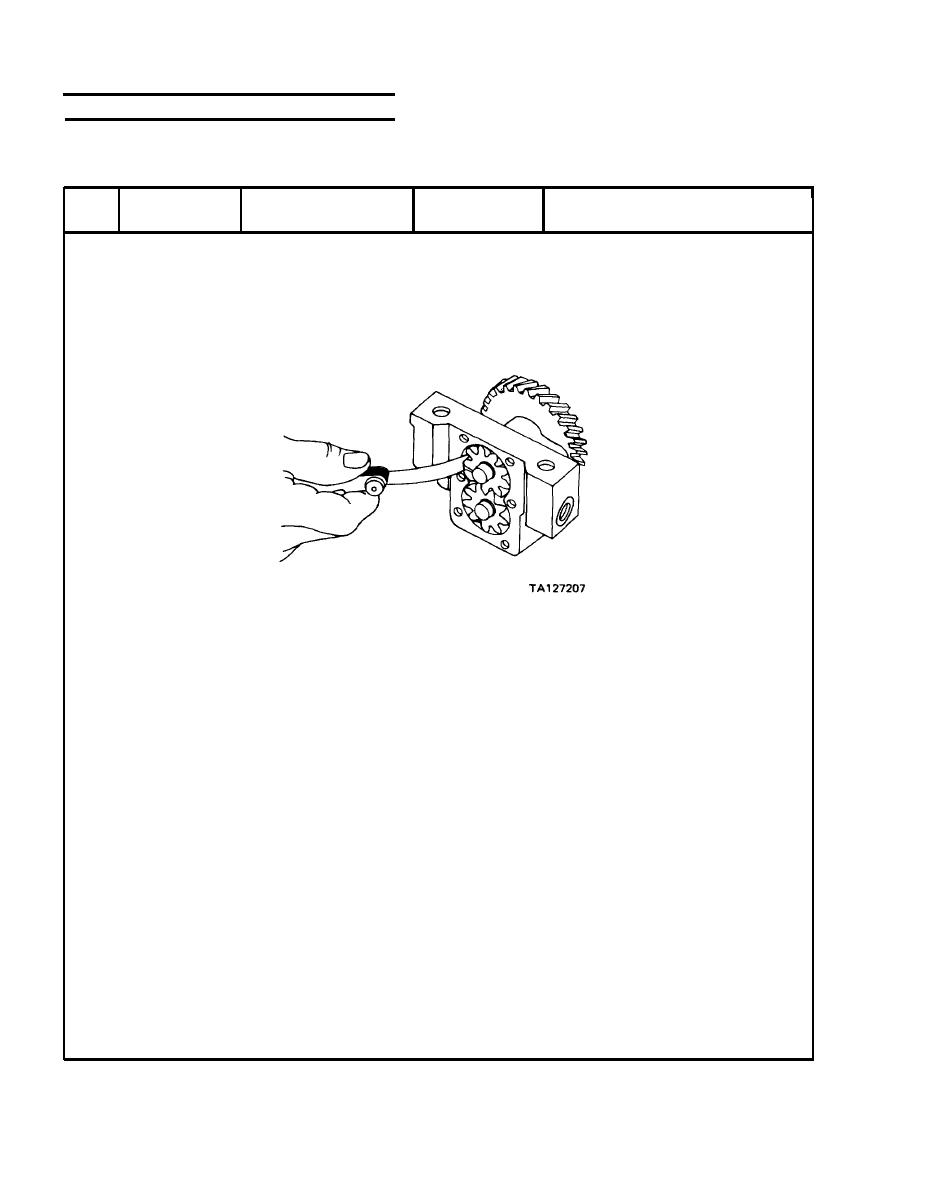

8

b. Pump gears

Check

Use feeler gage as shown and check pump

(Cont)

gears to body radial clearance. Clearance

shall not exceed 0.008 inch. Replace

oil pump if clearance exceeds this

dimension

c. Pump gears

Check

Place plasti gage on pump gear. Install

gasket (7), cover assembly (6), cap screw

(2), and lock washer (3), Tighten cap

screws to 6-8 pounds foot torque. Re-

move cover assembly and measure plasti

gage to obtain gear to cover clearance.

Clearance shall not exceed 0.008 inch.

Replace oil pump if clearance is greater

than this dimension

9

Relief valve spring (11)

lnspect

Check that free length is 2.125 inches

and that load required to compress spring

to 1.44 inches is 18-19 pounds. Replace

if none of these conditions are met

10

Oil pump

Inspect

Replace if screen torn, or if suction tube

screen (1)

bent, dented or cracked

11

Relief valve (12)

Inspect

Replace if damaged or distorted

and spring retainer (10)

REASSEMBLY

12

Oil pump

a. Relief valve (12)

Install

Closed end toward oil pump

body (13)

b. Relief valve spring

Install

(11)

c. Spring retainer (10)

Install

Closed end outward

4-72

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |