|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-638-24&P

4-2. ENGINE MAINTENANCE (cont)

g. Camshaft and Bearings (cont).

ITEM

ACTION

REMARKS

STEP

LOCATION

INSPECTION AND REPAIR

8

Inspect

Check surfaces for wear, damage, and

a. Overall

Camshaft (9)

scoring. If any of these conditions

observed, replace camshaft

Measure front

Use micrometer. Measure each bearing sur-

b. Bearing surfaces

face in four places. Measure front and rear

and rear

surfaces again, 90 degrees from first

measurement. If outer diameter of any

bearing surface is less than 1.748 inches,

replace camshaft.

9

a. Overall

Inspect

Replace if cracked, damaged or worn

Camshaft

Use micrometer. Replace if thickness is

thrust plate

b. Thickness

Measure

less than 0.147 inches

(8)

Inspect

10

Replace if cracked, or if teeth damaged or

Camshaft gear (6)

missing

Replace if cracked, damaged or worn

11

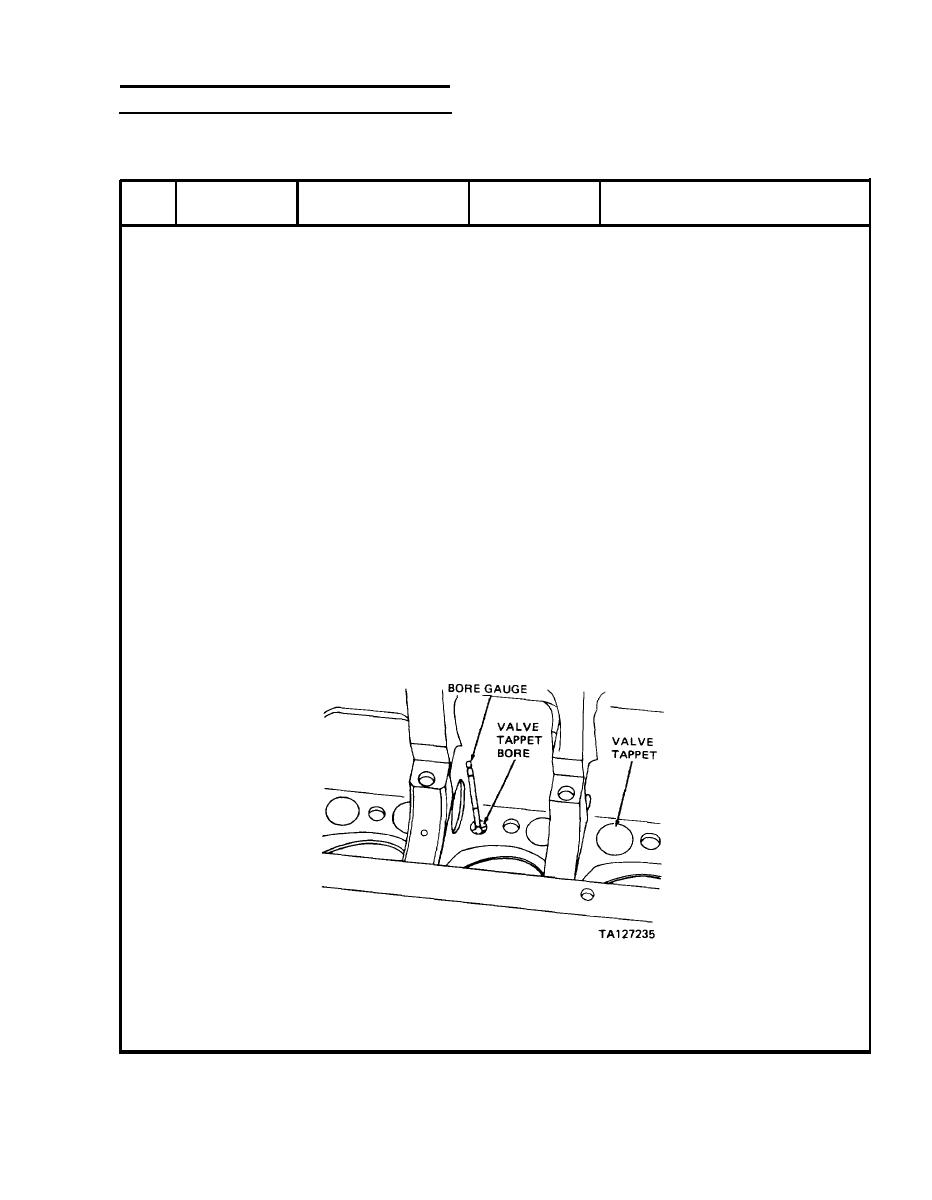

Valve tappet

a. Overall

Inspect

Measure

Replace if less than 0.5605 inch

b. Stem

(3)

outer diameter

Use bore gage. Replace cylinder block if

a. Valve tappet

12

Measure

Cylinder block,

greater than 0.5650 inch

inside diameter

bores

bottom

Use bore gage and measure in two places,

Measure inside

b. Camshaft

90 degrees apart. Replace if greater than

bushings (10,

diameter

1.755 inches

11, and 12)

4-55

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |