|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-638-24&P

4-2. ENGINE MAINTENANCE (cont)

d. Crankshaft and Main Bearings (cont).

REMARKS

ITEM

ACTION

STEP

LOCATION

INSPECTION (cont)

10

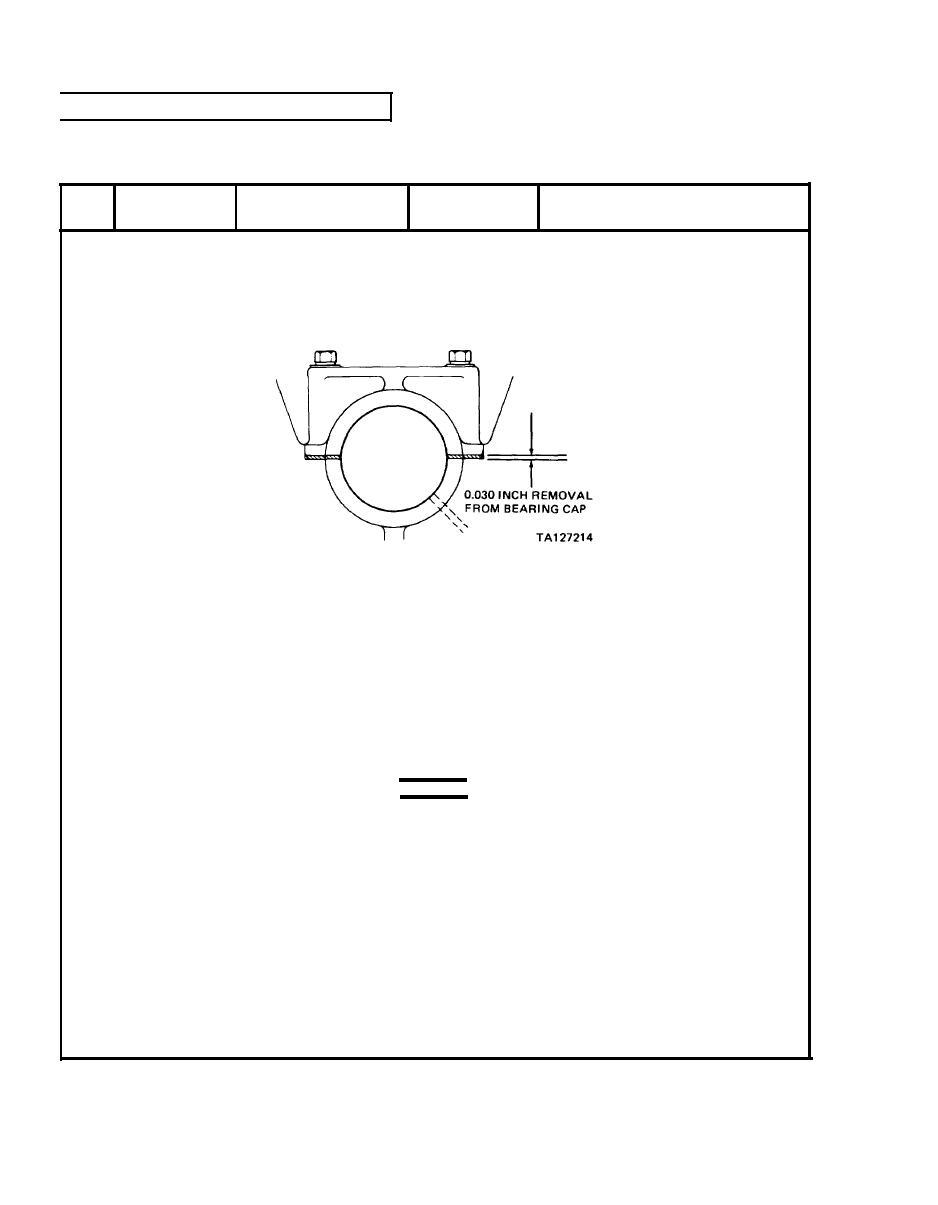

e. Replacement main

Remove and

Rework by removing 0.030 inch stock

(cont)

rework

bearing cap (4,

from mating surface. Then, bore out to

5,6, or 7)

meet tolerance specified in c above. If

0.039 inch stock is removed, machine

same amount from lock groove

NOTE

Machine new mounting surface flat so main bearing cap will set

solid without wobbling in cylinder block.

f. Two cap screws (3)

Remove

and replacement

main bearing cap

(4, 5,6, or 7)

INSTALLATION

11

Crankshaft (8)

a. Key (10)

Position

On crankshaft

WARNING

Wear asbestos gloves to prevent burning your hands when perform-

ing following step. If you burn your hands, obtain medical aid

immediately.

b. Crankshaft

Heat and

Use gear and bearing heater. Timing mark

gear (9)

install

on gear must be outward

12

Cylinder

a. Bearing liner

Clean

Remove all dust, dirt or grease. Dirt left

bore

behind bearing liners will interfere with

lubrication cooling resulting in hot spots

and premature failure of liners

4-32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |