|

|||

|

|

|||

|

Page Title:

FUEL SYSTEM TROUBLESHOOTING |

|

||

| ||||||||||

|

|

TM 10-3960-638-24&P

2-10. FUEL SYSTEM TROUBLESHOOTING

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. LOW FUEL PRESSURE

Check for air in fuel system

Step 1.

a. Place ignition switch in ON position.

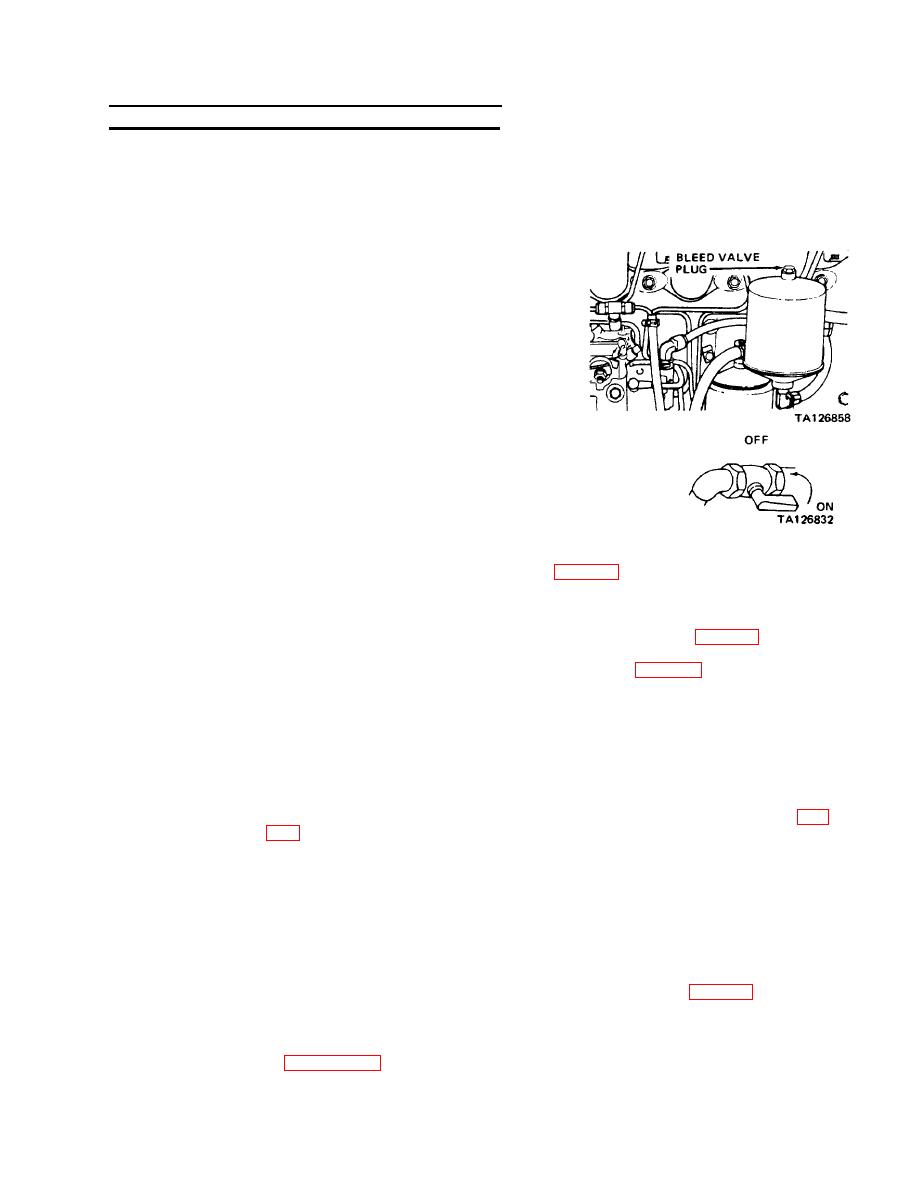

Open bleed valve plug on top of secondary fuel

filter allowing air to bleed out of both filters.

When fuel, free of bubbles, starts to flow, close

bleed valve plug and wipe parts free of fuel.

Turn ignition switch off.

b. If no air in fuel system, proceed to step 2 below.

Step 2.

Check if fuel shut-off valve is in closed position.

a. If in closed position, place in full on position as shown.

b. If in open position, proceed to step 3 below.

Check for leaks at fittings between fuel tank and fuel injection pump.

Step 3.

a. If leaks are observed, tighten or replace fittings (para 2-15d(2)).

b. If leaks are not observed, proceed to step 4 below.

Step 4.

Check fuel tank strainer, in-line fuel filter, and/or lines for clogged condition (para 2-15)

a. If strainer, fuel filter and/or lines are clogged, replace the part (para 2-1 5).

b. If strainer, fuel filter, and lines are okay, proceed to step 5 below.

Step 5.

Check for clogged fuel filters by disconnecting line between fuel filter head and fuel injection pump at

fuel injection pump.

Place ignition switch in ON position and crank engine.

Fuel should be pumped out of disconnected line.

a. If fuel is not pumped out of disconnected line, reconnect fuel line and service fuel filters (para

b. If fuel is pumped out of disconnected line, reconnect fuel line and proceed to step 6 below.

Disconnect fuel line at fuel filter head and connect to a tee fitting.

Step 6.

Connect a hose between other end of tee fitting and fuel filter head.

Connect pressure gage to tee fitting.

Place IGNITION switch in ON position.

Pressure gage shall indicate 4.5 to 6 PSI.

If pressure gage does not indicate 4.5 to 6 PSI, replace electric fuel pump (para 2-15b).

NOTE

If fuel injection pump is suspected to be cause of problem, perform

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |