|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-634-34

NOTE

Lip of oil seal (9, fig. 4-22) must be facing in-

ward when installed. Oil seal shall be pressed

five sixteenths of an inch below rear face of

bearing retainer.

C).

(d) Secure output shaft gear in a vise equipped

with soft jaws. Install output flange, new packing,

flange washer, and nut. Tighten nut to 200-250 lb-ft

torque. Install cotter pin.

(4) Stator Support. Reassemble stator support

g. Installation.

NOTE

Immerse gaskets and packings in clean trans-

mission oil.

(1) Install three pump drive shafts (fig. 4-28).

(2) Install pump adapters in reverse of numerical

sequence shown in figure 4-19.

(3) Install stator support (fig. 4-16).

(4) Install output shaft (fig. 4-18). Tighten screws

to specified torque.

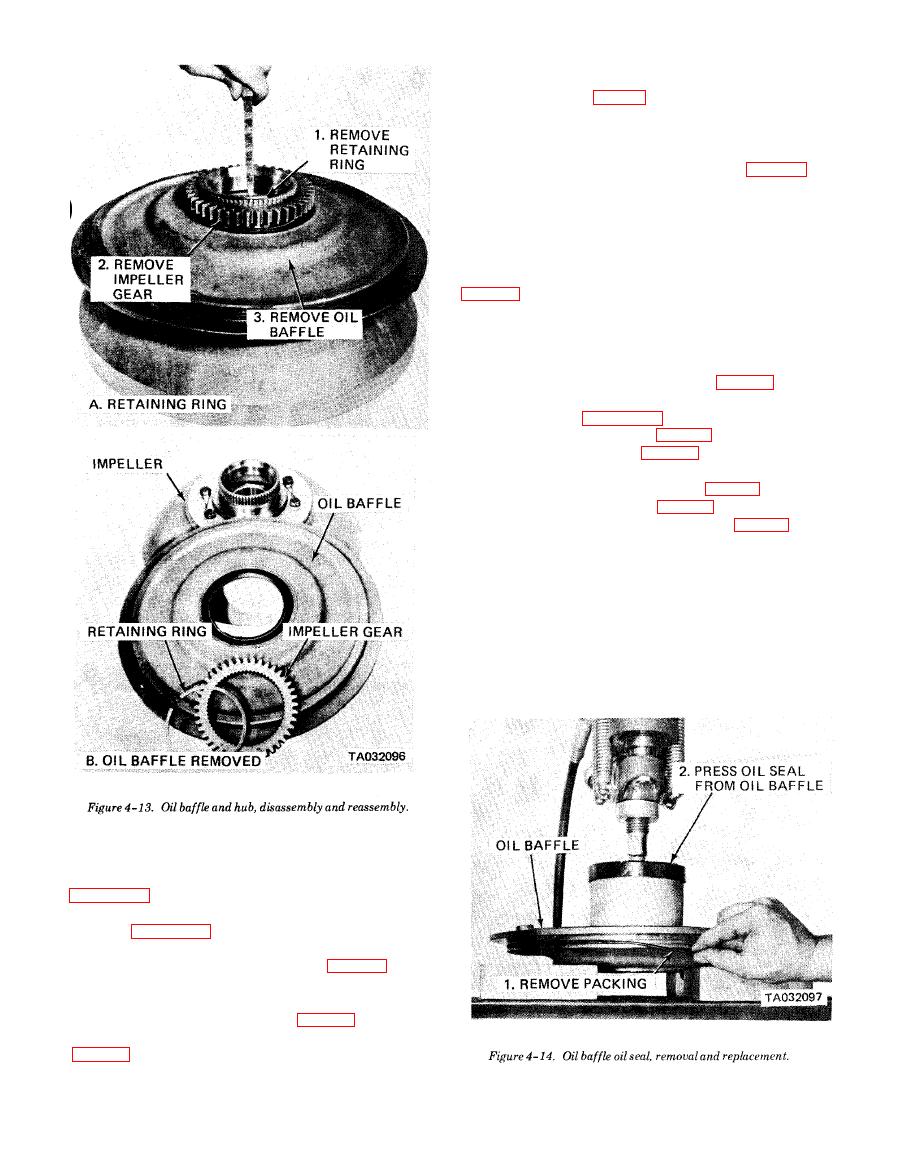

(5) Install impeller and oil baffle (para 4-4).

(6) Install charging pump (para 4-3).

(7) Install torque converter assembly (para 2-7).

(1) Converter Housing. Reassemble the converter

housing in reverse of numerical sequence as shown in

(2) Pump Shafts. Reassemble the pump shafts as

shown in figure 4-25.

(3) Output Shaft.

bearing retainer (8).

(b) Apply a thin coat of permatex No. 2 or equiv-

alent on outer diameter of seal (9, fig. 4-22) to assure

an oil tight fit. Press oil seal (9) in bearing retainer (8)

(fig. 4-26, A).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |