|

|||

|

|

|||

|

Page Title:

Installation of Main Bearings with Crankshaft Installed |

|

||

| ||||||||||

|

|

TM 10-3930-634-34

(7) Check the crankshaft end play by moving the

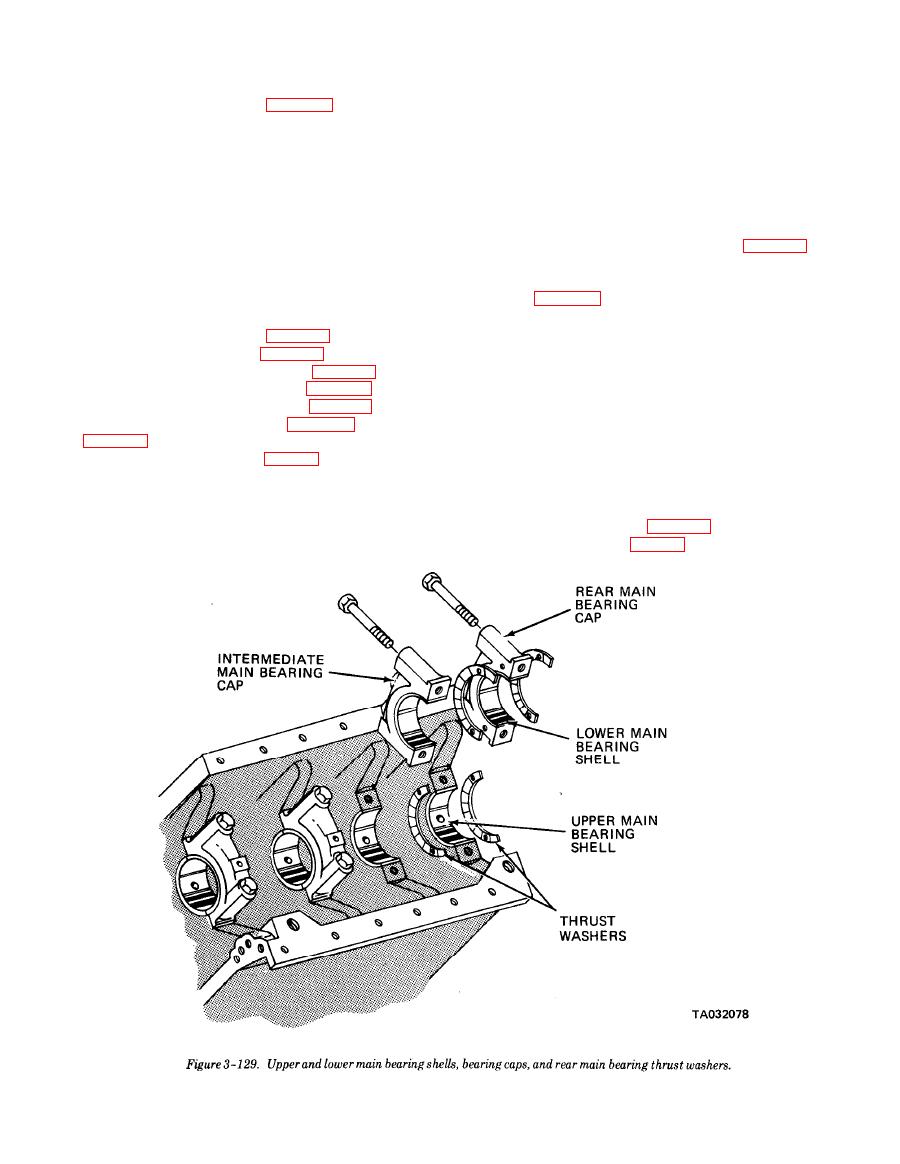

(2) Install new or original upper bearing shells af-

crankshaft toward the gage (fig. 3-140) with a pry bar.

ter inspection by rolling into place in the bearing sup-

Keep a constant pressure on the pry bar and set the

port.

dial indicator to zero. Then, remove and insert the

NOTE

pray bar on the other side of the bearing cap. Force the

Start the end of shell having no tang around

crankshaft in the opposite direction and note the

the crankshaft journal first, so that when

amount of end play on th dial. The end play should be

shell is in place the tang will fit into groove in

0.004 to 0.011 inch with new parts or a maximum of

shell support.

0.018 inch with used parts. Insufficient end play can

(3) Install the upper thrust washers (fig. 3-131).

be the result of a misalined rear main bearing or a burr

(4) Position the lower bearing shell and the lower

or dirt on the inner face of one or more of the thrust

thrust washer halfs (on rear bearing cap only) in bear-

washers.

ing caps (fig. 3-131) and install over crankshaft rear

(8) Install connecting rods to the crankshaft (para

bearing journal.

3-34).

(5) Position lower bearing shells in remaining

(9) Install rocker arms (para 3-23).

bearing caps and position on crankshaft journals.

(10) Install fuel pipes (para 3-18).

(6) Secure bearing caps as instructed in (b) (6) and

(11) Install rocker arm covers (para 3-16).

(7) above.

(12) Install flywheel housing (para 3-33).

(13) Install lower front cover (para 3-31).

NOTE

(14) Install oil inlet tube (para 3-27) and oil pan

If the main bearings have been installed prop-

erly, the crankshaft will turn freely.

(15) Install the engine (para 2-5).

(7) Check crankshaft end play (para h (7) above).

i. Installation of Main Bearings with Crankshaft In:

(8) Install the oil inlet tube and screen (para

stalled.

3-27).

(1) Apply clean engine oil to all crankshaft jour-

(9) Install the oil pan (para 3-26).

nals and install the main bearing shells (one at a time)

(10) Install engine (para 2-5).

in reverse of removal.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |