|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-634-34

(9) Install the flywheel housing (para 3-33).

(4) Install capscrew (3, fig. 3-126) and tighten to

(10) Install the engine (para 2-5).

30 to 35 lb-ft of torque. Remove the two pilot cap-

screws installed above.

3-37. Crankshaft and Main Bearings

(5) Lubricate the idler gear hub and idler gear

a. General.

bearings with clean engine oil.

(1) The crankshaft is a one-piece steel forging,

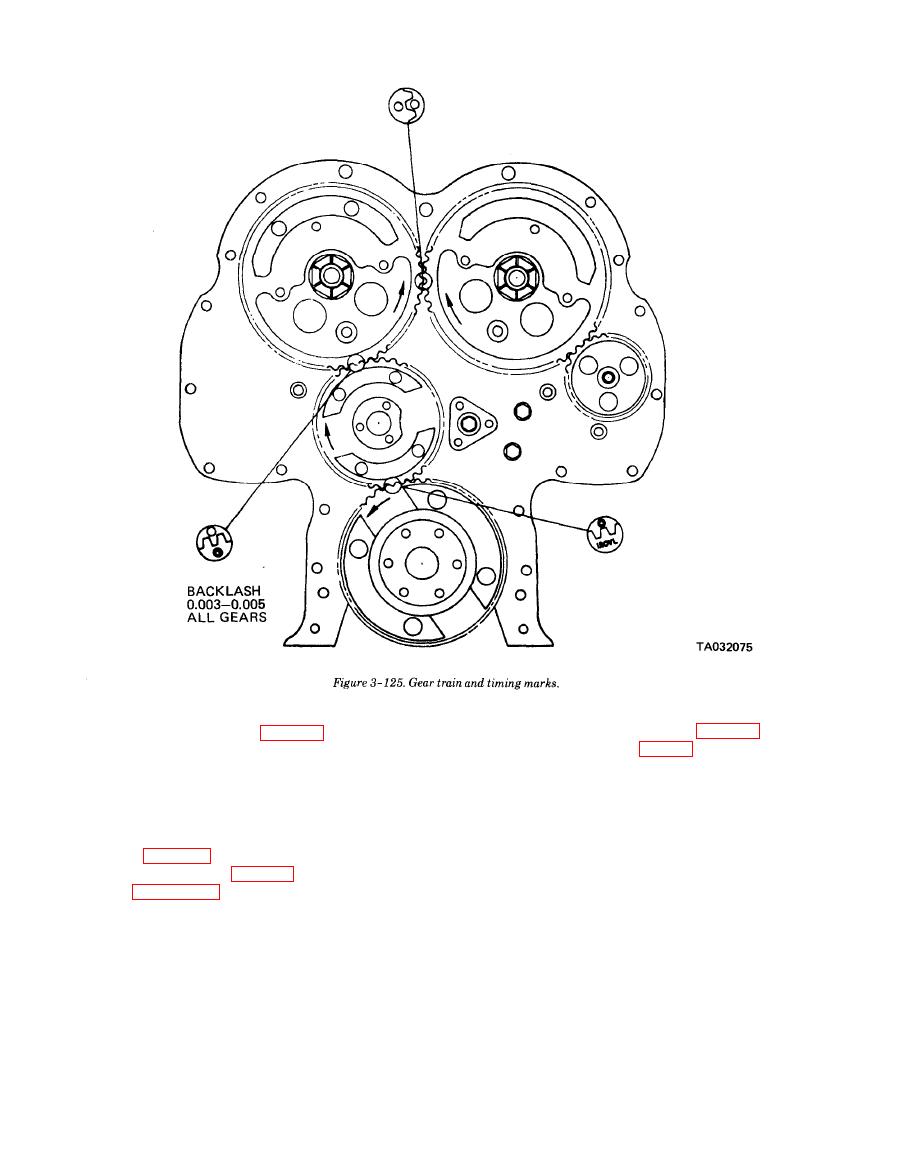

(6) Position the crankshaft gear and the camshaft

heattreated to insure strength and durability. All main

gear so the timing marks will aline with those on the

and connecting rod bearing journal surfaces and oil

idler gear (fig. 3-125). With these marks in alinement,

seal surfaces are induction hardened. Complete static

install the idler gear (6, fig. 3-126) on the hub (5) as

and dynamic balance is achieved by counterweights.

shown in figure 3-128.

(2) The main bearing shells are of the precision

(7) Apply a thin film of cup grease to the inner

type and may be readily replaced without machining.

face (face with the oil grooves) of the outer thrust

They are used at each crankshaft main journal and

washer (4). Place the thrust washer over the hub with

consist of an upper shell seated in the cylinder block

grooves toward the gear and the flat in the inside di-

main bearing support and a lower shell seated in the

ameter of the thrust washer over the flat on the gear

main bearing cap. Bearing shells are prevented from

hub.

endwise or radial movement by a tang at the parting

(8) Check the backlash between the mating gears.

line at one end of each shell. The bearing caps are num-

The backlash should be 0.003 to 0.005 inch between

bered 1, 2, 3 and 4, indicating their respective position

new gears and should not exceed 0.007 inch between

and, when removed, must always be reinstalled in

used gears.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |