|

|||

|

|

|||

|

Page Title:

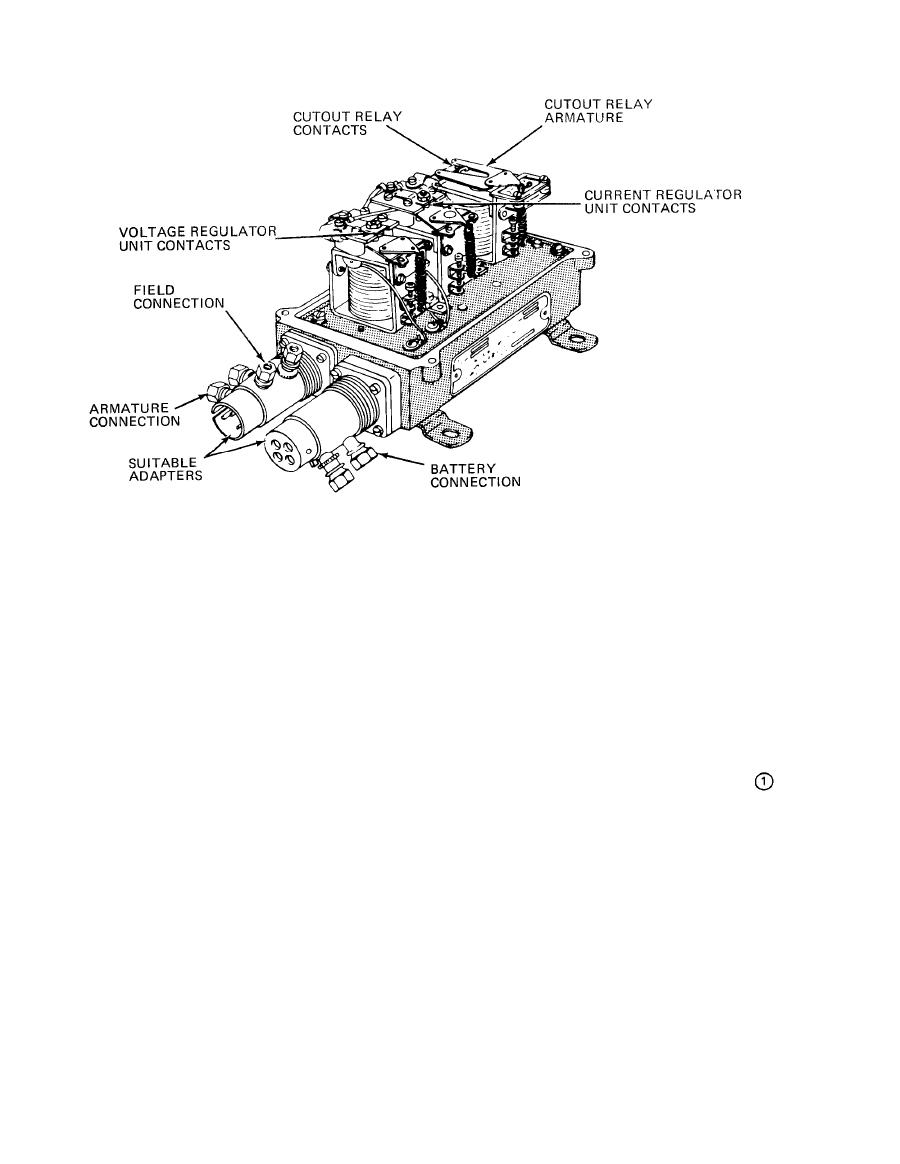

Figure 3-8. Voltage regulator adjustment (sheet 1 of 5). |

|

||

| ||||||||||

|

|

TM 10-3930-634-34

1. INSTALL SUITABLE ADAPTER IN THE CONNECTORS OF THE REGULATION UNIT.

2. USE A MULTIMETER AND TEST FOR CONTINUITY BETWEEN THE ARMATURE CONNECTION

OF THE TEST ADAPTER AND THE CUTOUT RELAY ARMATURE. CONTINUITY SHOULD

BE INDICATED.

3. CLOSE THE CIRCUIT BREAKER CONTACTS AND TEST BETWEEN THE ARM AND BATTERY

CONNECTIONS OF THE TEST ADAPTERS. CONTINUITY SHOULD BE INDICATED.

4. TEST BETWEEN THE ARMATURE AND FIELD CONNECTIONS OF THE TEST ADAPTERS.

ZERO RESISTANCE SHOULD BE INDICATED.

5. OPEN THE VOLTAGE REGULATOR UNIT CONTACTS. 175 HMS, THE RESISTANCE OF THE

SHUNT RESISTOR, SHOULD BE INDICATED.

6. CLOSE THE VOLTAGE REGULATOR UNIT CONTACTS AND OPEN THE CURRENT REGULATOR

UNIT CONTACTS. 150 OHMS, THE RESISTANCE OF THE SHUNT RESISTOR SHOULD BE

INDICATED.

7. REPLACE THE REGULATOR IF IT FAILS TO MEET THE ABOVE REQUIREMENTS.

TA032034

group to the starter terminal and the starter housing.

the armature at the drive end. Adjust the rheostat to

give 3.52 volts. The correct readings are 500 amperes

Connect an ammeter to the shunt and a direct current

maximum and a stall torque of 20 lbs-ft minimum. The

voltmeter to the starter terminal and starter housing.

stall torque is the product of the spring scale reading

With the voltage adjusted to 22.5 volts, the current

in pounds multiplied by the torque arm in feet. If the

should be 80 amperes maximum at 3,600 rpm. If the

current and speed are both low, inspect for high resis-

current and torque are both low, inspect for high re-

sistance in the internal connections and for improper

tance in the internal connections. If the current is high

brush contact. High current and low torque may be

and the speed is low, inspect the bearing and armature

caused by a defective armature or field coil.

for binding and incorrect alinement.

the starter (TM

Install

i. Installation.

(2) Stall torque test. With the starter connected as

10-3930-634-12).

in (1) above, fasten a torque arm and a spring scale to

3-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |