|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-634-34

CHAPTER 3

REPAIR OF ENGINE

Section I. COOLING SYSTEM

(3) Immerse the radiator in a vat of water and

3-1. General

apply air pressure at 5-10 psi. Leaks will be indicated

This section contains information on the mainte-

by escaping air bubbles.

nance of the engine cooling system which is comprised

CAUTION

of the radiator, water pump, fan, and oil cooler.

Air pressure exceeding 10 pounds per square

3-2. Radiator

inch may damage the radiator core.

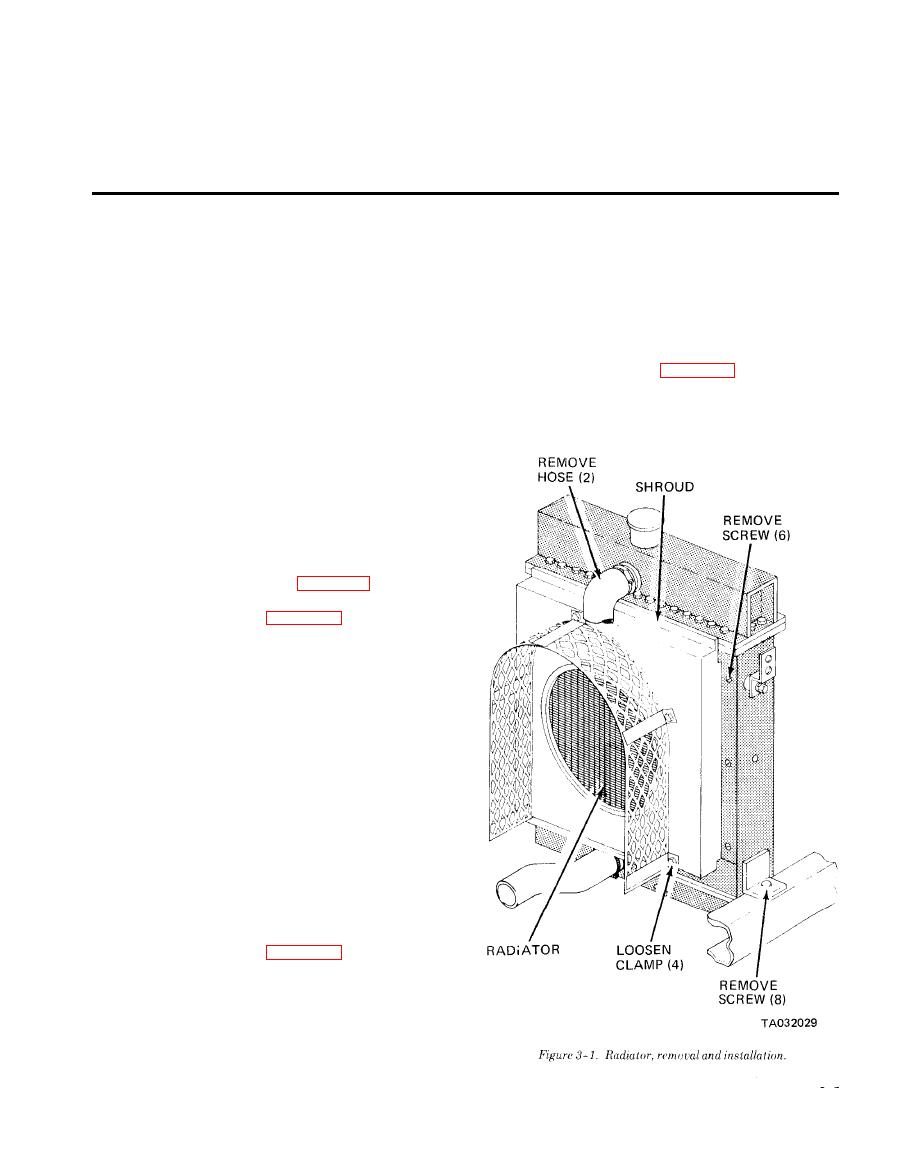

g. Installation. Refer to figure 3-1 and install the

a. General. The radiator assembly is bolted to the

radiator.

front of the engine base (at the rear end of forklift). To

increase the cooling efficiency of the radiator, a fan

shroud is positioned around the fan. A fan guard is

securely attached to the shroud. The water pump is a

high-capacity centrifugal type. It is belt-diven at

greater than engine speed, and it circulates the coolant

through the cooling system.

b. Removal.

(1) Remove the engine hood (TM 10-

3930-634-12).

(2) Open the draincock at the bottom of the radia-

tor and drain coolant. Refer to figure 3-1 and remove

the radiator.

c. Disassembly. Refer to figure 32 and disassemble

the radiator in numerical sequence.

d. Cleaning and Inspection.

(1) Inspect the external condition of the radiator.

( 2 ) Inspect mounting hardware for rust and

breaks.

(3) Inspect the radiator core and inside of radiator

for scale deposits.

(4) Steam cleaning is the preferred method of

cleaning the radiator. The radiator may also be cleaned

using the alkaline immersion process with cleaning

c o m p o u n d P-C-436. After use of this process,

thoroughly rinse until free of alkaline solution.

(5) Examine each part for cracks or other damage.

(6) When repainting the radiator core, use a thin

coat of dull, black radiator paint. Ordinary oil paints

do not transmit heat as well.

(7) Repair or replace a defective radiator. Solder

all leaks in the core. Replace all defective parts.

e. Reassembly. Refer to figure 3-2 and reassemble

the radiator in reverse of numerical sequence.

f. Testing.

(1) If a leak in the radiator cannot be located, plug

the inlet, filler and overflow pipes.

(2) Insert an air hose into the outlet pipe and plug

opening.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |