|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-634-34

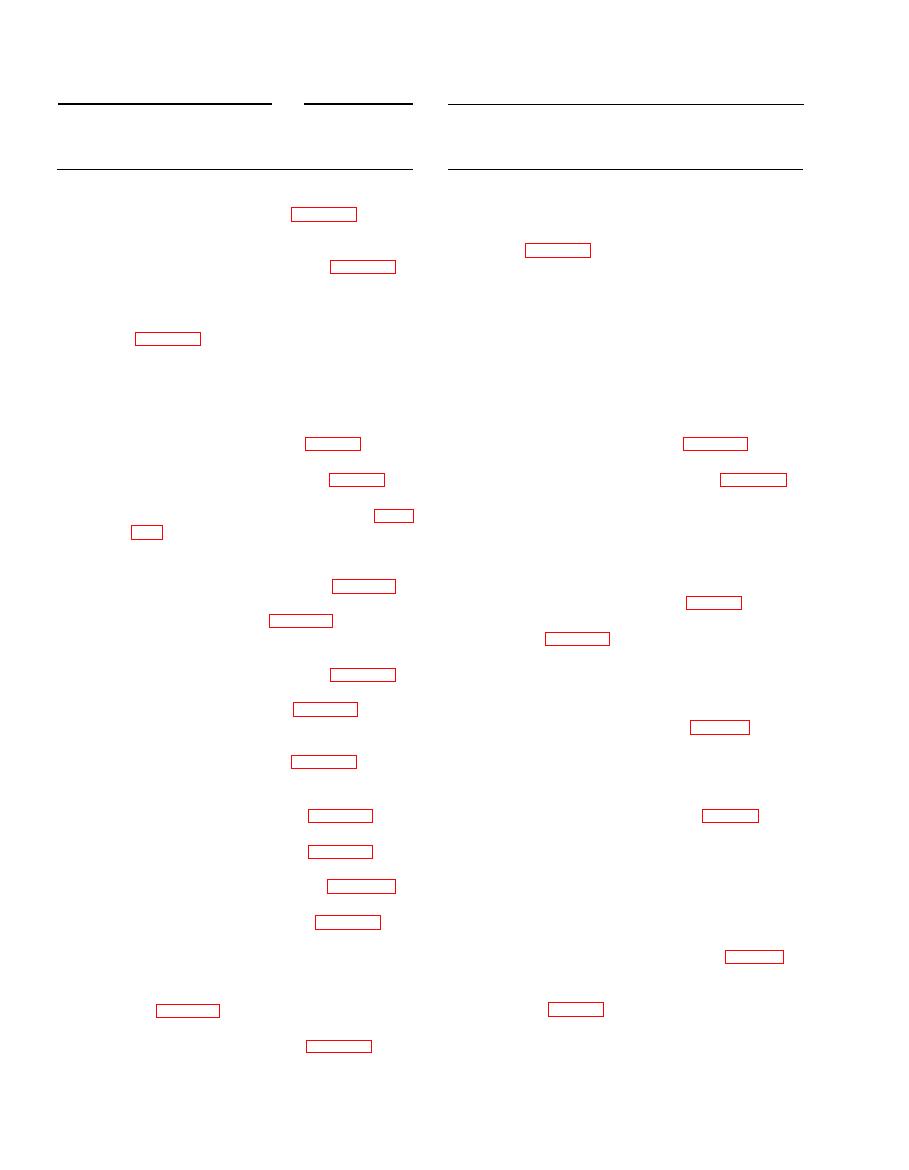

Table 2-2 TroubleshootingContinued

Table 2-2. Troubleshooting--Continued

MALFUNCTION

MALFUNCTION

TEST OR INSPECTION

TEST OR INSPECTION

CORRECTIVE ACTION

CORRECTIVE ACTION

Step 3. Check for defective connecting-rod

Step 2. Check fordefective valves.

Repair or replace valves (para 3-20).

bearings.

Replace defective connecting-rod bearings

Step 3. Check for low compression caused by

broken or worn piston rings.

Step 4. Check for loose or defective main bear-

Replace defective piston rings (para 3-34).

ings.

Step 4. Check fordefective push rods or rocker

Replace defective main bearings (para

arms.

3-37).

Replace defective push rods or rocker arms

ENGINE OIL CONSUMPTION EXCESSIVE.

8.

Step 1. Check for broken or worn piston rings.

Step 5. Check for proper functioning of gover-

nor.

R e p l a c e defective pistons rings (para

3-34).

Adjust or replace governor.

Step 2. Check for cracked, burned, or broken

4.

ENGINE OVERHEATS.

piston.

Step 1. Check for defective radiator.

Replace defective piston (para 3-34).

Repair or replace radiator (para 3-2).

Step 3. Check for worn valve guides.

Step 2. Check for defective water pump.

Repair or replace water pump (para 3-3).

Replace defective valve guides (para 3-25),

9.

STARTER FAILS TO CRANK ENGINE.

Step 3. Check for cracked cylinder head.

Step 1. Check for defective engine safety cir-

Replace defective cylinder head (para

cuit.

Isolate circuit trouble and repair (para

ENGINE EXHAUST SMOKE EXCESSIVE.

5.

3-9).

Step 1. Check for defective fuel injector.

Step 2. Check for defective starter.

Repair or replace fuel injector (para 3-18).

Repair or replace starter (para 3-9).

Step 2. Check for restricted air intake,

Step 3. Check for defective flywheel ring gear

Clean blower screen (para 3-13).

Step 3. Check for low compression caused by

10.

broken or worn piston rings.

LOW OR NO CHARGING RATE WHEN BAT-

Replace defective piston rings (para 3-34),

TERIES ARE LOW OR DISCHARGED.

Step 4. Check for cracked or broken piston.

Step 1. Check for defective generator brushes.

Replace defective piston (para 3-34).

ENGINE NOISY,

6.

Replace defective brushes (para 3-7).

Step 2. Check for defective voltage regulator.

Step 1. Check for defective valves.

Repair or replace valves (para 3-25).

Repair or replace voltage regulator (para

3-8).

Step 2. Check for defective connecting-rod

Step 3. Check for defective armature.

bearings.

Replace defective armature (para 3-7).

Replace defective bearings (para 3-34).

Step 4. Check for defective field windings.

Step 3. Check for defective main bearings.

Replace defective field windings (para

Replace defective bearings (para 3-37).

3-7).

Step 4. Check for loose or broken piston pins.

11.

Replace defective pistons pins (para 3-34).

CHARGE WHEN BATTERIES ARE FULLY

Step 5. Check for loose or defective flywheel.

CHARGED.

Tighten or replace flywheel (para 3-32).

Step 1. Check for ground field winding.

7.

ENGINE HAS LOW OR NO OIL PRESSURE.

Replace defective field winding (para 3-7).

Step 1. Check for oil dilution caused by leaking

Step 2. Check for defective voltage regulator.

fuel line or injector.

Repair or replace defective voltage regula-

Correct leak or replace defective fuel injec-

tor (para 3-8).

tor (para 3- 18).

Step 2. Check for defective oil pump.

Repair or replace oil pump (para 3-31).

2-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |