|

|||

|

|

|||

|

Page Title:

chapter 3 OPERATOR/CREW MAINTENANCE INSTRUCTIONS |

|

||

| ||||||||||

|

|

TM 10-3930-634-12

OPERATOR/CREW MAINTENANCE INSTRUCTIONS

Section I. LUBRICATION INSTRUCTIONS

tion points clean before lubricating the equipment.

Clean all lubrication points of excessive lubricants

This section contains information on lubrication in-

after servicing to prevent a buildup or accumulation of

structions not covered in the current lubrication order.

foreign matter.

Refer to the current lubrication order for all other

lubrication instructions.

CAUTION

Overlubrication may cause equipment

failure or damage to working parts.

c. Points of Lubrication. Service the lubrication

containers and store in a clean, dry place away from

points at the intervals described in the current lubrica-

heat. Keep container cover clean and in good repair.

tion order.

Keep dust, dirt and all other foreign material out of the

d. Intervals of Lubrication. The intervals of lubrica-

lubricant. Keep all lubrication equipment clean and

tion specified in the lubrication order are based on

ready for use.

opertion under normal conditions. Modification of the

recommended intervals may be required under unusual

b. Cleaning. Keep all external parts that do not re-

operating conditions.

quire lubrication free of lubricants. Wipe all lubrica-

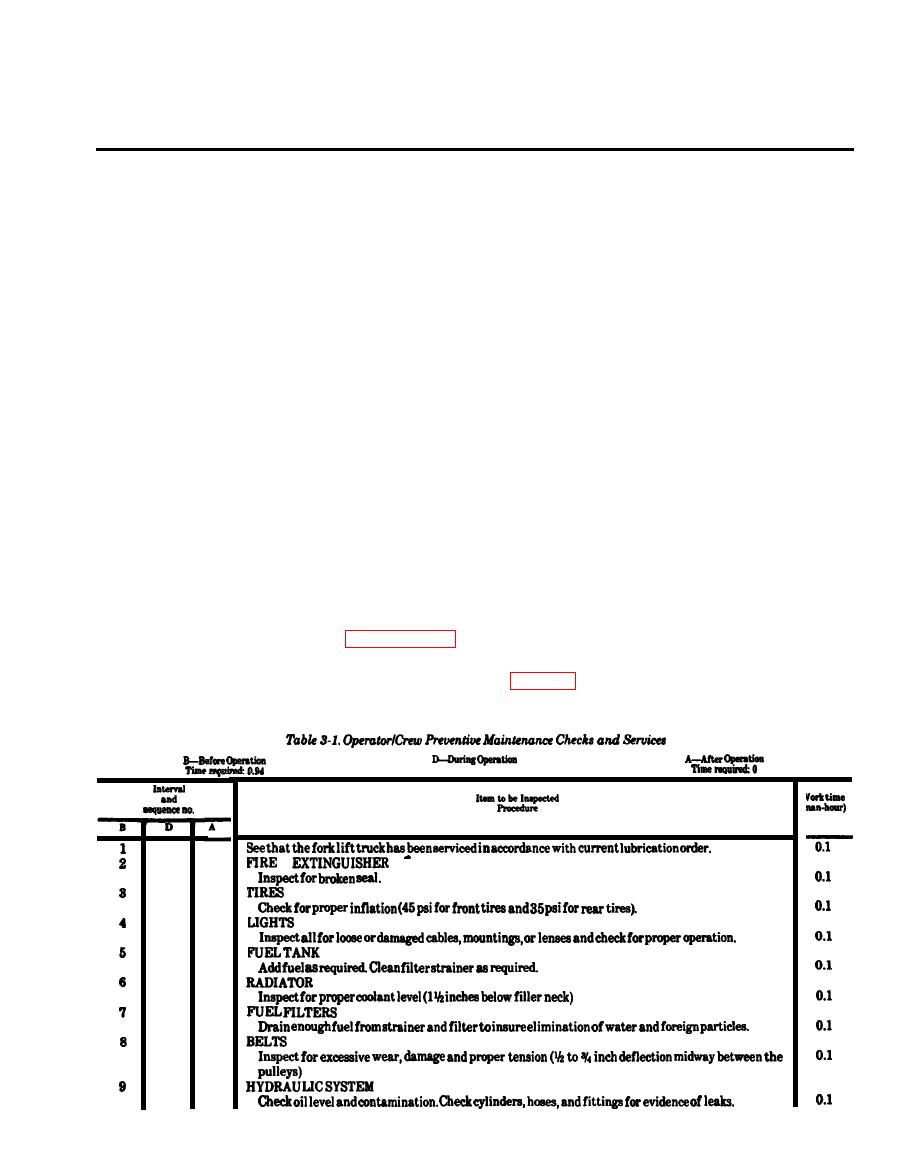

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

3-3. General

the equipment if operation were continued. All defi-

ciencies and shortcomings will be recorded, together

To insure that the forklift is ready for operation at all

with the corrective action taken, on DA Form 2404

times, it must be inspected systematically so that

(Equipment Inspection and Maintenance Worksheet)

defects may be discovered and corrected before they

at the earliest possible opportunity.

result in serious damage or failure. The necessary pre-

ventive maintenance checks and services to be per-

formed are listed and described in paragraph 3-4.

Services

Defects discovered during operation of the unit shall be

Preventive maintenance checks and services are listed

noted for future correction to be made as soon as opera-

in tables 3-1 and 3-2. These services must be performed

tion has ceased. Stop operation immediately if a defi-

by the operator/crew at the intervals and sequences in-

dicated in the tables.

ciency is noted during operation which would damage

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |