|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-34

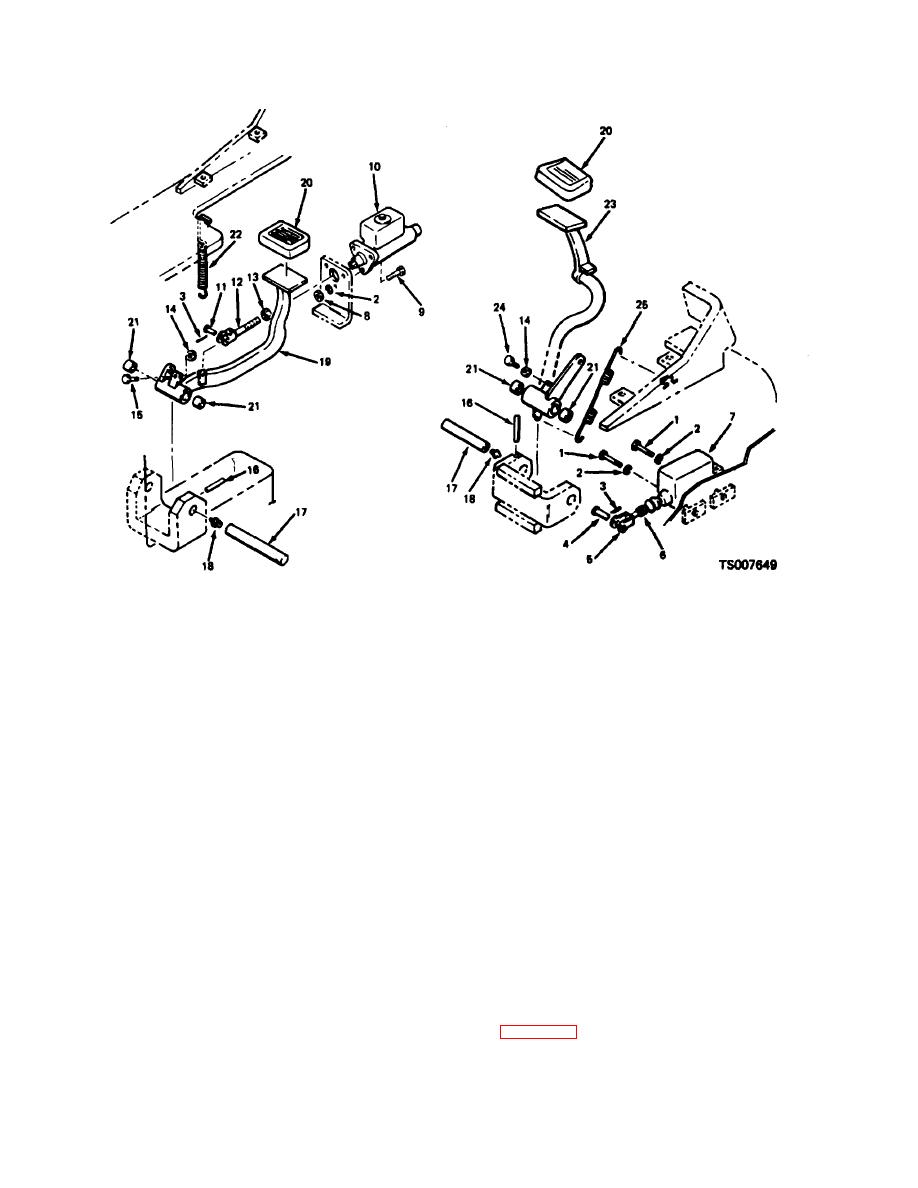

15.

Stop bolt

2.

Lockwasher

16.

Spring pin

3.

Cotter pin

17.

Pivot shaft

4.

Clevis pin

18.

Lubrication fitting

5.

Clevis rod end

19.

Inching brake pedal

6.

Jam nut

20.

Pedal pad

7.

Service master cylinder

21.

Needle bearing

8.

Nut

22.

Return spring

9.

Bolt

23.

Service brake pedal

10.

Inching master cylinder

24.

Stop bolt

11.

Clevis pin

25.

Return spring

12.

Clevis rod end

13.

Jam nut

Figure 11-1. Brake Pedal and Linkage. Exploded View.

c.

Inspect the brake pedals (23 and 19) for

WARNING

cracks or evidence of bending or stress.

d.

Check pivot bushings and shafts carefully for

Dry cleaning solvent, P.D480, used to clean

wear or damage.

parts is potentially dangerous to personnel and

e.

Inspect springs (25 and 22) for broken or

property. Avoid repeated and prolonged skin

cracked coils and signs of fatigue.

contact.

Do not use near open flame or

excessive heat. Flash point of solvent is 100 F.

- 138 F. (39 F. - 90 C.).

11-5.

Reassembly and Installation

Reassembly and installation is essentially the

11-4.

Cleaning and Inspection

reverse of removal and disassembly and may be

a.

Clean all metal parts with a cloth dampened in

accomplished by reversing the order of indexing depicted

solvent, Federal Specification P.D.680.

in figure 11-1.

b.

Wipe all grease or oil deposits from brake

pedal pads with a dry cloth.

11-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |