|

|||

|

|

|||

|

Page Title:

Section X. PISTONS AND CONNECTING RODS |

|

||

| ||||||||||

|

|

TM 10-3930-632-34

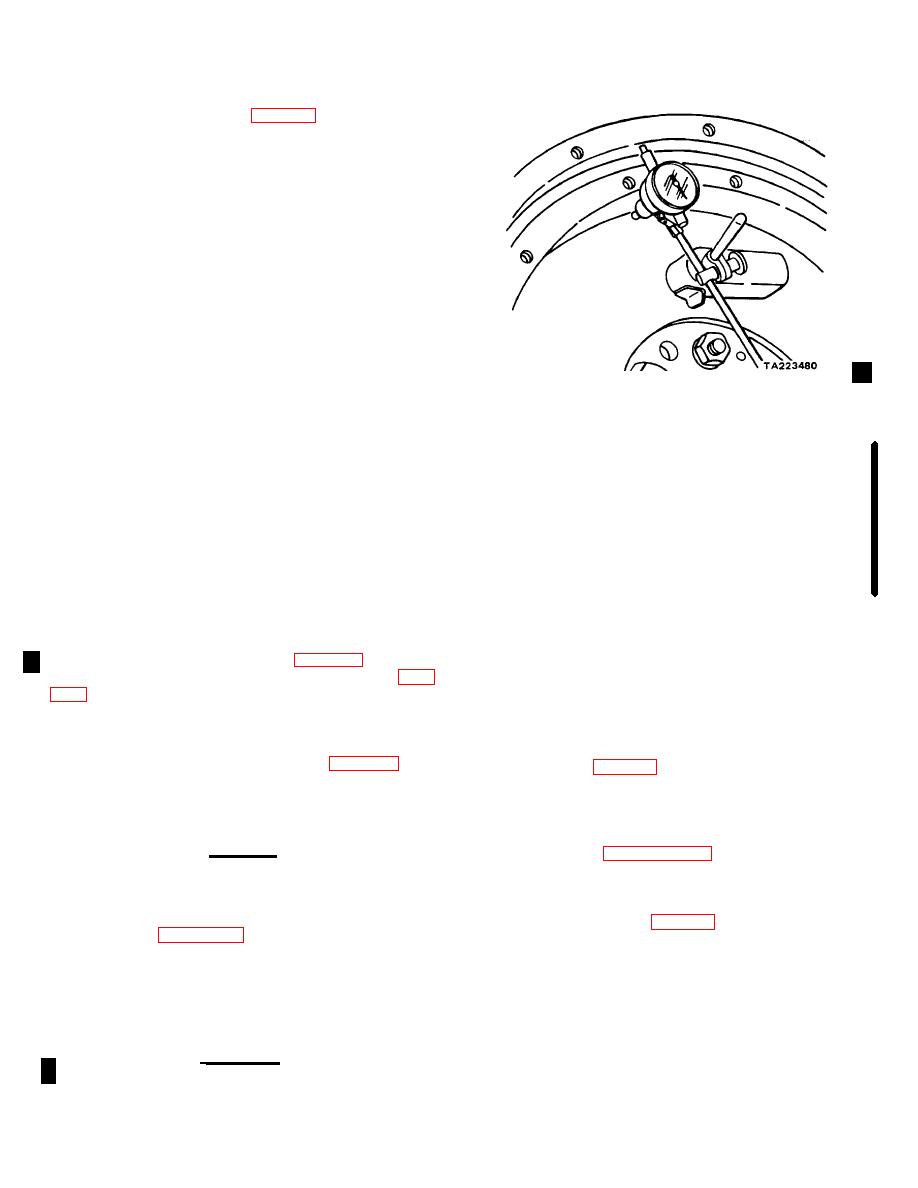

f.

Check eccentricity of the flywheel housing bore

by mounting a dial indicator (fig. 9-24) and rotating the

engine through one revolution. If the housing bore is

eccentric more than 0.008 inch, loosen the flywheel

housing mounting bolts and tap the housing into its

proper position with a soft hammer. Tighten the bolts

and recheck eccentricity of the housing bore. If the

housing cannot be brought into true position, replace the

housing.

Figure 9-24. Checking Flywheel Housing Eccentricity.

Section X. PISTONS AND CONNECTING RODS

and use only in a well ventilated area. Avoid

9-26.

General

contact with skin, eyes, and clothes and don't

The engine uses aluminum pistons, each of which is

breathe vapors. Do not use near open flame or

fitted with three compression rings and one oil control

excessive heat. The flash point is 100F -

ring. The forged steel connecting rods transfer the force

138F. (38C - 59C). If you become dizzy while

from the pistons to the crankshaft. Close-fitting bearing

shells are installed between the connecting rod and the

using cleaning solvent, get fresh air immediately

crankshaft journals.

and get medical aid. If contact with eyes is

made, wash your eyes with water and get

9-27.

Removal and Disassembly

medical aid immediately.

With the engine mounted on an engine overhaul

stand, proceed as follows:

9-28.

Cleaning and Inspection

a.

Remove the cylinder head (para 9-6).

a.

Discard and replace the piston rings.

b.

Remove the engine oil pan and oil pump (para

b.

Clean all parts with cleaning solvent P-D-680

and dry thoroughly.

c.

Ream the ridge of the top of each cylinder

c.

Inspect the pistons for cracks, distortion,

bore with a standard ridge reamer.

Blow metal

broken ring lands and distorted grooves, loose piston

fragments from the cylinder with compressed air.

pin-to-piston fit and other damage; replace damaged

d.

Remove the two cotter pins (19, fig. 9-20) and

pistons. Refer to table 9-1 for wear limits.

nuts (20) that secure a bearing cap to a connecting rod

NOTE

(21); remove the cap and rod bearing (22).

Pistons and bearings are individually checked

e.

Push assembled piston (15) and connecting

and fitted to the cylinders at reassembly. Before

rod (21) up through the top of the block.

reassembly. the cylinder bores must be checked

CAUTION

as directed in paragraph 9-41.

While pushing the piston and rod from the block,

be very careful the connecting rod does not

d.

Inspect the connecting rods for cracks,

scratch the cylinder wall.

distortion, and other damage; replace damaged

connecting rods. Refer to table 9-1 for wear limits,

f.

Refer to figure 9-20 (items 12 through 21) and

e.

Inspect the bearing shells for scoring, wear,

disassemble the piston and connecting rod.

cracks, and other damage.

NOTE

NOTE

Disassemble the pistons and piston rods in sets,

New bearing shells are smooth and highly

and keep the sets together. Also, be sure each

polished. After a few hours of operation, the

piston and piston rod set is installed In the

bearing surface becomes a leaden grey and

cylinder from which it was removed.

develops minute craters so

WARNING

Dry cleaning solvent P-D-680 is toxic and

flammable. Wear protective goggles and gloves

Change 1 9-18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |