|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-34

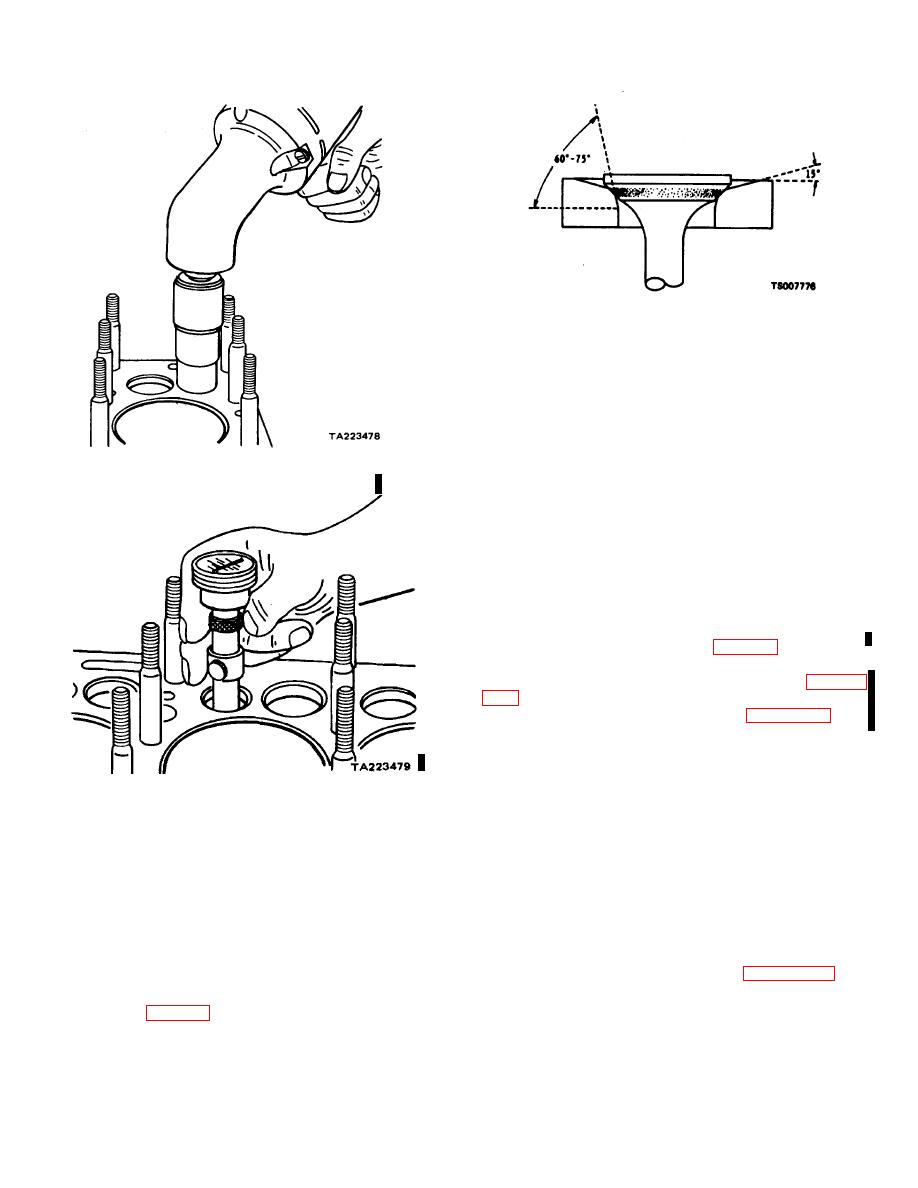

Figure 9-12. Narrowing Valve Seat.

k.

Inspect the spring retainer seat, spring

retaining locks, valve stem caps, and valve tappet

assemblies for cracks, scoring, overheating, and wear.

Replace damaged parts.

9-13.

Installation

a.

Position the valve tappet assemblies (8, fig. 9-

Figure 9-10. Grinding Value Seat.

6) in the engine block.

b.

Assemble the valves (1 and 2), valve springs

(5), spring retainer seats (9), and valve locks (7).

Compress the valve springs with a spring compressor to

install the valve locks. Turn the engine over as necessary

to allow each valve to move to the closed position before

attempting to install the valve parts. Make sure each

valve is installed in the guide from which it was removed.

c.

Temporarily set valve tappet clearance.

d.

Install the cylinder head (para 9-9).

e.

Operate the engine until it reaches operating

temperature. Adjust valve tappet clearance (para 9-

f.

Install the valve tappet cover (para 9-13.1).

9-13.1.

Valve Adjustment

a.

Operate engine until it reaches operating

Figure 9-11. Checking Valve Seat turnout.

temperature.

b.

Remove the nuts and washers that secure the

j.

After the valves and seats have been refaced

valve tappet cover to the cylinder block. Remove the

and reground, coat the seat lightly with Prussian blue and

valve tappet cover and gasket.

drop the valve into place oscillating it slightly to transfer

c.

With the engine at operating temperature and

the blue pattern to the valve face. This should show a

running at idle speed, set the valves for 0.012-inch

contact width of 1/16 to 3/32 inch, and should fall well

clearance as follows:

within the width of the valve face, leaving at least 1/64

(1) Check for proper 0.012-inch intake valve

inch on either side of the contact area. If the contact area

clearance by alternately passing an 0.011-inch and an

is greater than 3/32 inch, narrow the contact area by

0.013-inch flat feeler gage between the head of the

grinding the outside diameter of the seat with a 15 stone

adjusting screw and intake valve stem (figure 9-12.1).

or by grinding the inside diameter of the seat with a 60

(2) If an 0.011-inch feeler gage moves freely

back and forth in the gap when the valve is not being

or 76 stone (fig. 9-12). After the seat area is corrected,

lifted and an 0.013-inch feeler gage binds at

touch the seat lightly with the original grinding stone to

remove the burred or feathered edge.

Change 1 9-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |