|

|||

|

|

|||

|

Page Title:

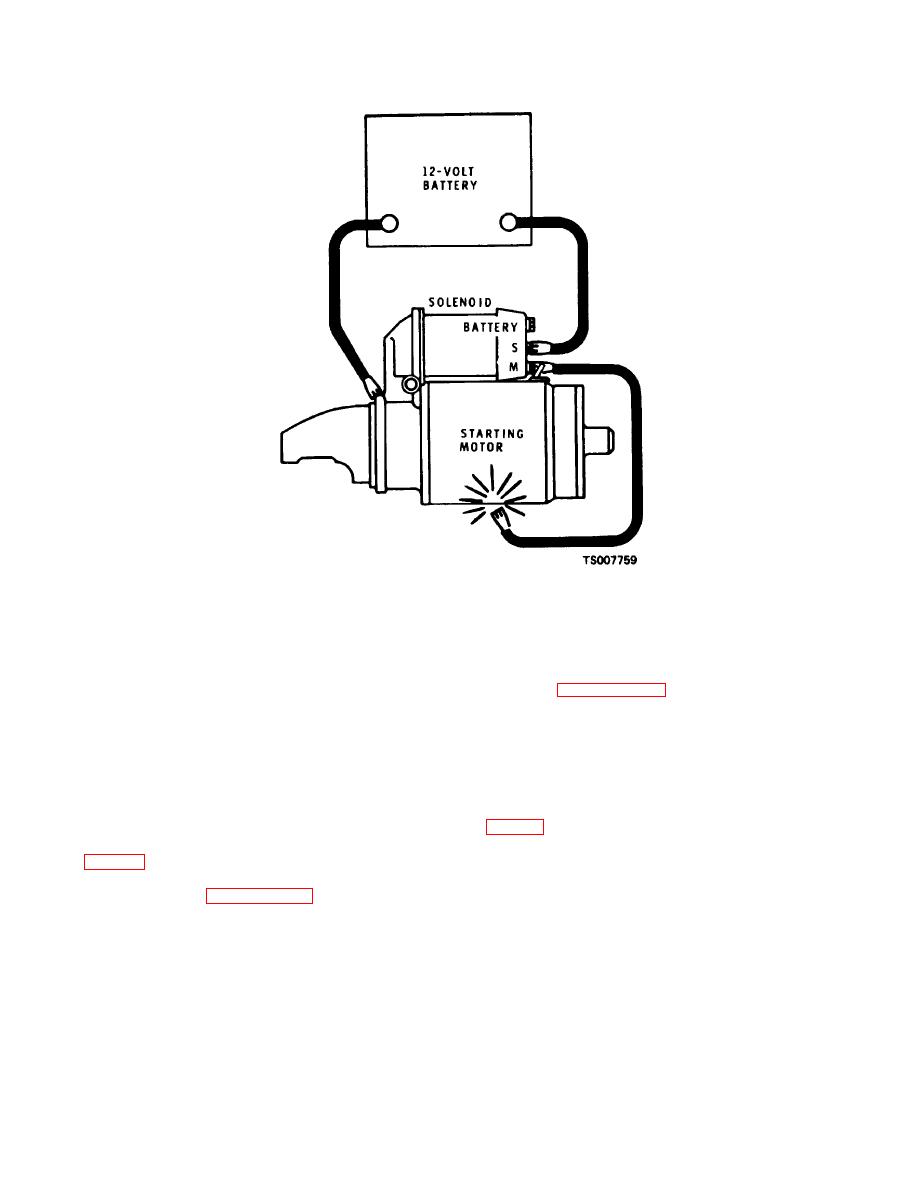

Figure 5-3. Circuit for Checking Pinion Clearance. |

|

||

| ||||||||||

|

|

TM 10-3930-632-34

Figure 5-3. Circuit for Checking Pinion Clearance.

alignment of the collar (23) on the retaining ring (24).

CAUTION

I.

Before installation, test the engine starter as

directed in paragraph 5-12, below.

Insulate the motor field lead carefully to avoid

arcing during the checking procedure.

5-12.

Testing

g. Momentarily touch the jumper lead from the

To assure that the engine starter is fully restored to

solenoid motor terminal to the motor frame. This will

operating condition after overhaul, test it as follows:

shift the pinion into cranking position. It will stay in this

a. Connect the engine starter, a 12-volt battery, an

position until the battery is disconnected.

h. Push the pinion back toward the commutator

end to eliminate all slack movement. Measure the

distance between the pinion gear of the drive assembly

resistance until the voltmeter reads 9 volts.

The

(26, fig. 5-2) and the collar (23). If clearance is not

ammeter must read between 50 and 80 amperes and the

between 0.010 and 0.140 inch, disassemble the starting

armature speed must be between 5500 and 10,500 RPM

motor as described in paragraph 5-9 above and check

as indicated on a tachometer held against the shaft.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |