|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-632-12

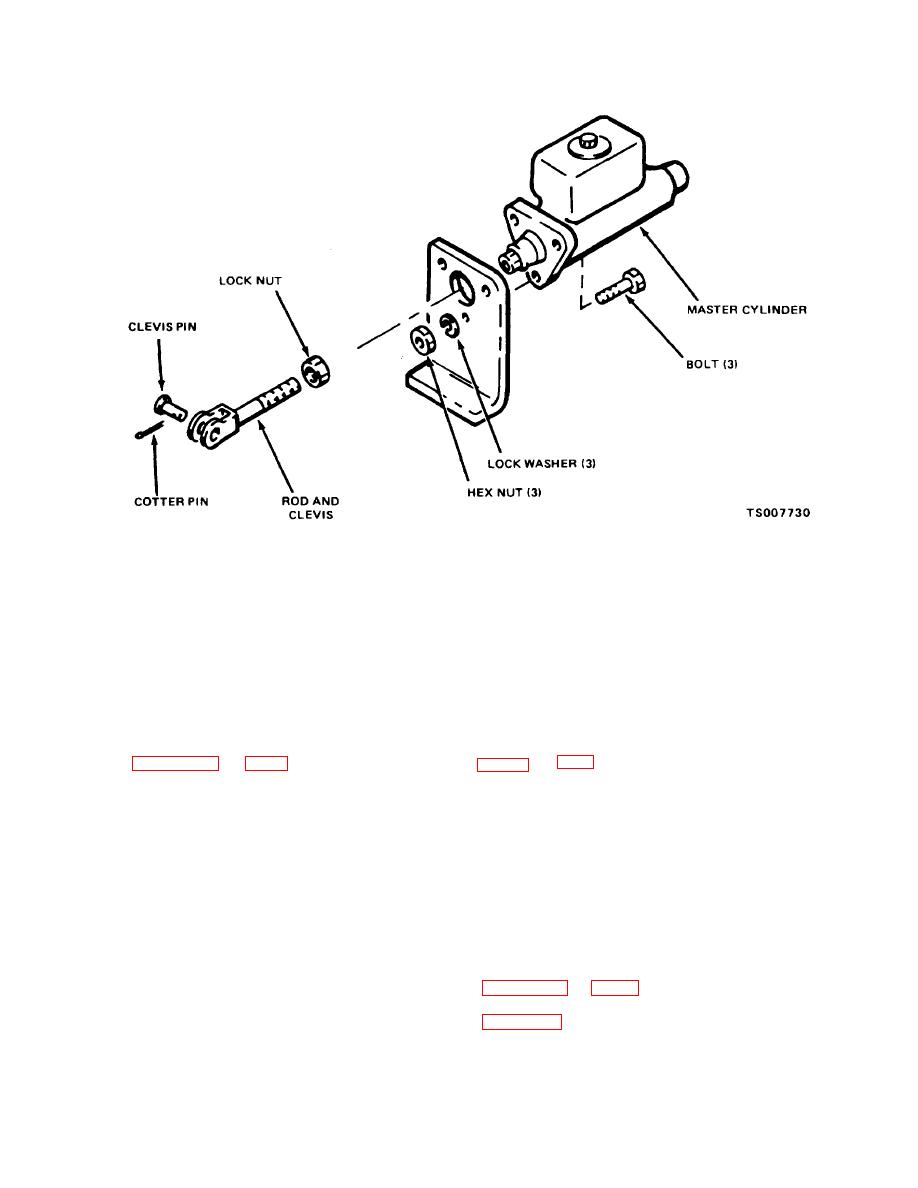

Figure 4-57. Inching Brake Master Cylinder, Removal and Installation

a. Removal

pedals at rest in the full "up" position. Loosen locknuts

and turn the screws in or out as required. Tighten

(1) Remove the accelerator pedal from

locknuts when the correct adjustment is obtained.

floor plate.

(2) Hold a ruler vertically against some

(2) Remove floor plate.

stationary point under the floor board so that the scale

(3) Disconnect hydraulic brake lines from

portion rests against the pedal pad of either pedal. Push

master cylinder.

CAUTION

on the pedal, by hand, noting the point at which

resistance is felt. The pedal should travel a minimum of

When disconnecting brake lines, take care to

1/8 inch and a maximum of 1/4 inch when resistance is

prevent dirt from entering the brake system.

felt. To adjust free play on either pedal, refer to figures

(4) Remove one or both master cylinders

as shown in figures 4-56 and 4-57.

WARNING

master cylinder push rod clevis. Loosen locknuts on the

clevis and turn clevis in or out as required. Turning

Dry cleaning solvent, P-D-680, used to clean

clevis in will increase pedal free play; turning out will

parts is potentially dangerous to personnel and

decrease free play. Tighten locknuts and install clevis

property. Avoid repeated and prolonged skin

pin when correct adjustment is obtained.

contact.

Do not use near open flame or

(3) Inspect the brake master cylinders for

excessive heat. Flash point of solvent is 100F.

cracks, leaks and faulty operation; replace if damaged.

-138F. (380 C. -60C.).

b. Cleaning and Inspection.

(4) Inspect the brake lines for cracks,

dents, collapsed walls, restrictions, damaged threads,

(1)

Clean the exterior of the master

and other damage; replace damaged brake lines.

cylinders with a clean cloth dampened with dry cleaning

c. Installation.

solvent P-D-680.

(1) Install the master cylinders as shown in

(2) Wipe the exterior of the brake lines

and fittings with a cloth dampened with dry cleaning

(2) Connect the brake lines as shown in

solvent P-D-680. Flush the interior of the lines with

solvent. Blow dry with compressed air. To obtain the

(3) Bleed the brake system as outlined in

dimensions shown above, adjust the stop screws with

Change 1 4-73

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |