|

|||

|

|

|||

|

Page Title:

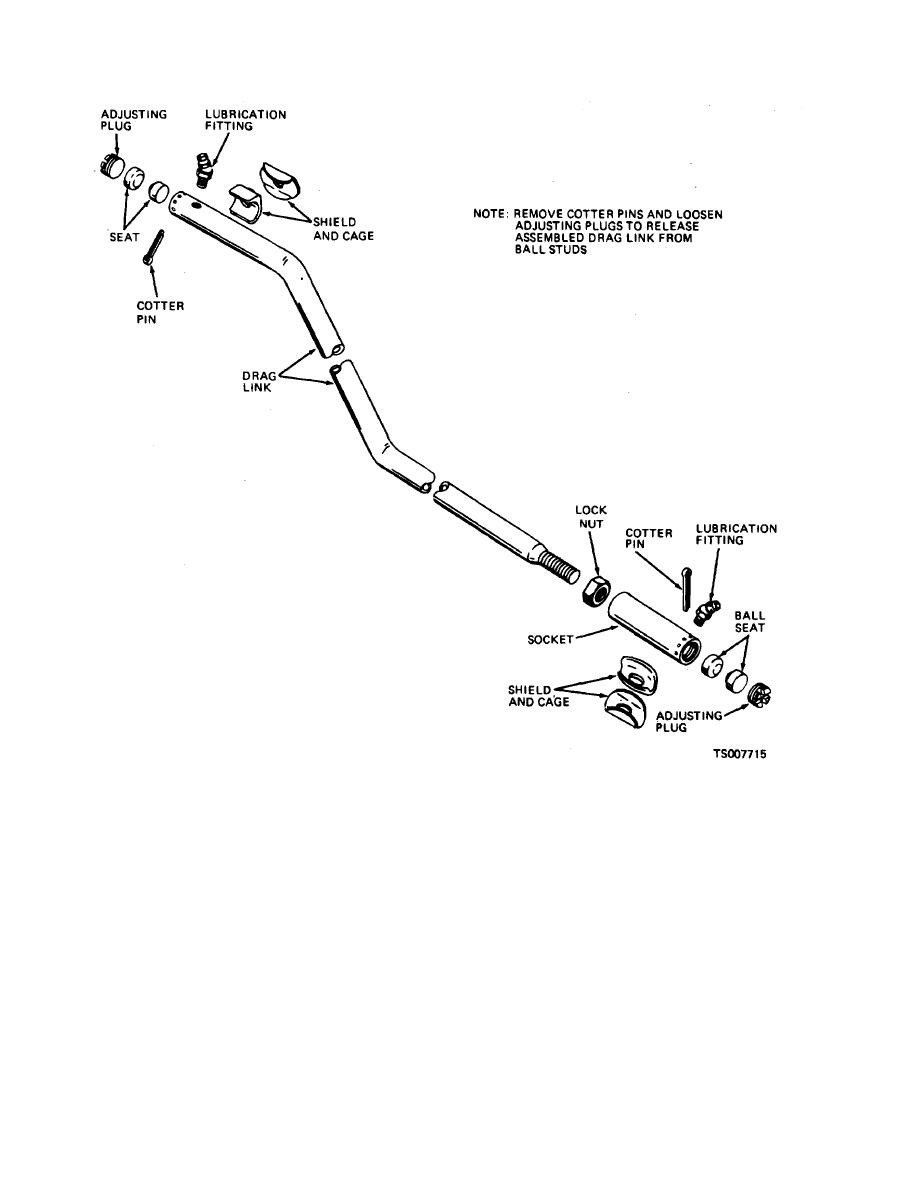

Figure 4-42. Drag Link, Disassembly and Reassembly |

|

||

| ||||||||||

|

|

TM 10-3930-632-12

Figure 4-42. Drag Link, Disassembly and Reassembly

WARNING

(3) Inspect the drag link and socket for

cracks, distortion, damaged threads, and severe dents;

Dry cleaning solvent, P-D-680, used to

replace if damaged.

clean parts is potentially dangerous to

(4) Inspect all other parts for cracks,

personnel and property. Avoid repeated

distortion, damaged threads, and other damage; replace

and prolonged skin contact. Do not use

damaged parts.

near open flame or excessive heat. Flash

c. Reassembly, Installation, and Adjustment.

point of solvent is 100F.-138F. (38C.-

(1) Lubricate the seating surfaces of the

60C.).

b. Cleaning and Inspection.

ball seats with grease of the type indicated in the

lubrication chart, prior to assembly.

(1) Clean the metallic parts of the drag link

(2) Turn steering handwheel to full right

with dry cleaning solvent P-D-680.

turn position. Turn handwheel back 1/4 turn minimum.

(2) Inspect the ball seats for cracks, wear

(3)

Install assembled drag link with

or scoring of the seating surfaces, and other damage;

steering

replace damaged parts.

4-58

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |