|

|||

|

|

|||

|

Page Title:

Table 4-3. Temperature-Voltage and Temperature-Current Chart for Adjusting Voltage Regulator |

|

||

| ||||||||||

|

|

TM 10-3930-632-12

Table 4-3. Temperature-Voltage and Temperature-Current Chart for Adjusting Voltage Regulator

Ambient temperature of regulator

65

85

105

125

145

165

185

(F.)

Voltage setting (volts) connect per

14.4-15.4

14.2-15.2

14.0-14.9

13.8-14.7

13.5-14.3

13.1-13.9

Current setting (amperes) connect per

25-30

24.5-20

23.5-28

23-27

21.5-25.5

20.5-24.5

19.5-23.5

CAUTION

WARNING

Dry cleaning solvent, P-D680, used to clean

Check airgap and point gap opening with

the battery disconnected.

parts is potentially dangerous to personnel

(3) Test and adjust the cutout relays as

and property.

Avoid repeated and

follows:

prolonged skin contact. Do not use near

(a) Measure the airgap of the cutout

open flame or excessive heat. Flash point

relay between the armature and the core with the

of solvent is 100F. -138F. (38C. -60C.).

contact points barely touching. The airgap should be

(2)

Clean the contact points of the

0.020 inch. If the points do not close, align the lower

regulator when they show signs of oxidation and pitting.

contact bracket slightly or bend the spring fingers on the

Oxidation of the contacts reduces the generator output.

armature until the points meet and align. Adjust the

Clean the thicker (tungsten) contact points with a riffler

airgap by loosening the two screws attaching the lower

file until the oxidation is removed. Clean the thinner

contact bracket. Raise or lower the contact bracket as

(platinum) contact with crocus cloth; wash with dry

required. Align the contact points and tighten the

cleaning solvent P-D-680 to remove any oily film. Blow

screws. Measure the contact point opening; it should be

the filings from the unit with compressed air to prevent

0.020 inch. Adjust to obtain the correct contact point

them from becoming embedded in the contact surfaces.

CAUTION

opening by bending the upper armature stop. To test

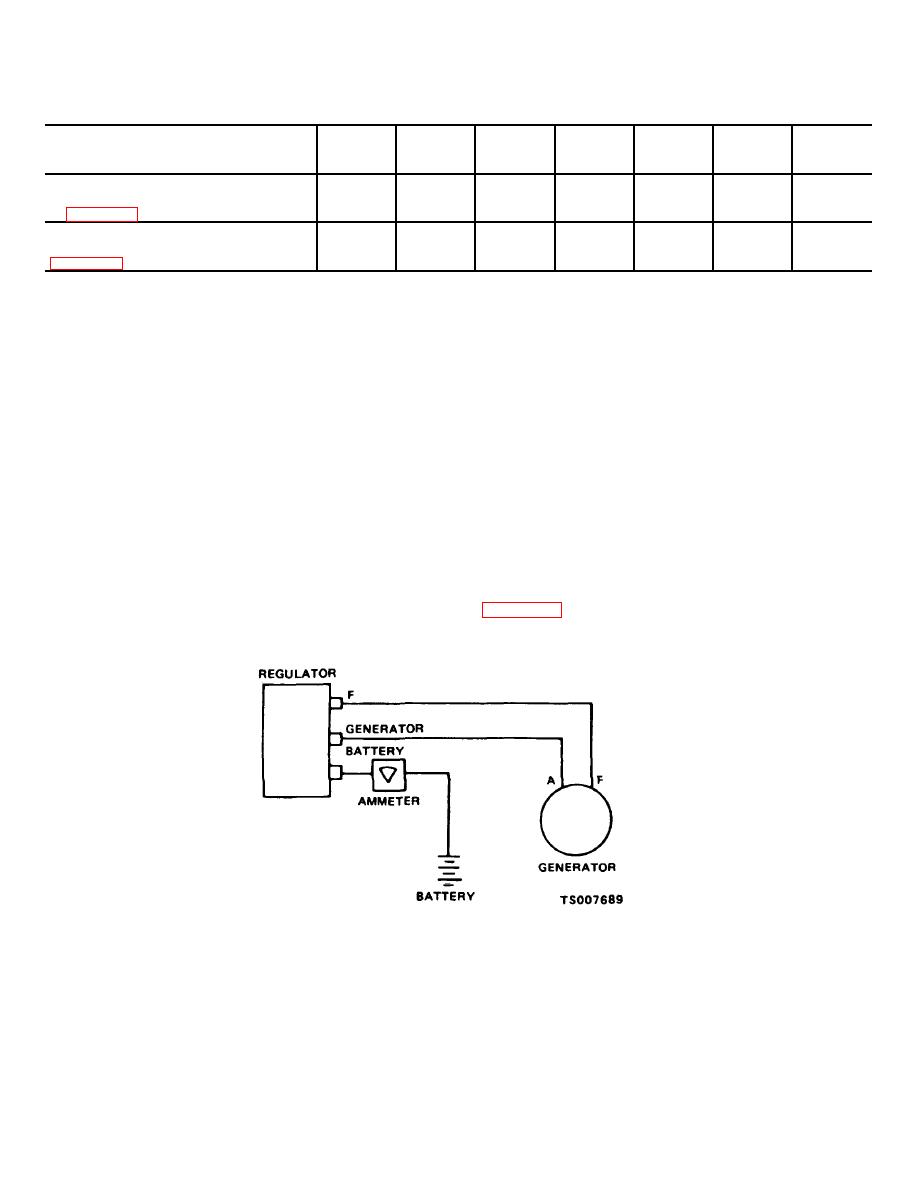

the closing voltage, connect the regulator as shown in

Do not file the contact points excessively.

Never use sandpaper or emery cloth. Use a

clean ignition file.

Figure 4-16. Cutout Relay Closing Voltage Test Circuit

CAUTION

voltage regulator. This will cause high

current to flow through the units and

Never close the cutout relay contact points

seriously damage them.

by hand with the battery connected to the

4-32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |