|

|||

|

|

|||

|

Page Title:

Section XIII. ELECTRICAL SYSTEM |

|

||

| ||||||||||

|

|

TM 10-3930-632-12

c. Cleaning.

idle speed, raise and lower the carriage and operate the

tilt cylinder. Refill the hydraulic tank. Check for leaks.

(1) Discard and replace the filter element

and gaskets.

4-29. Hydraulic Reservoir Breather

(2) Clean metal filter components with dry

cleaning solvent P-D-680; dry with clean, dry

a. Removal. Remove the hydraulic reservoir

compressed air. Clean the interior of the hydraulic tank

with a clean cloth. Rinse with 2 quarts of hydraulic oil.

breather (fig. 4-12) by unscrewing it from the hydraulic

(3) Inspect the filter case for cracks,

reservoir filler pipe.

b. Cleaning. Clean the hydraulic reservoir

distortion, damaged mounting flange, and other

damage; replace if damaged.

breather by tapping it on a wood block or bench while

(4) Inspect the cover for cracks, scored or

rotating the breather. This procedure is intended to

damaged outlet connection, studs that are loose or have

dislodge particles caught in the air filter. Replace the

damaged threads, or a damaged mounting flange.

breather after it has been in service for 500 operating

d. Reassembly. Reassemble the filter as

hours.

shown in figure 4-12.

e. Refilling Hydraulic Tank. Fill the hydraulic

tank to the bottom of the filler tube. With the engine at

Section XIII. ELECTRICAL SYSTEM

4-30. General

The electrical wiring diagram for the fork lift truck is

shown in figure 1-3. Power to operate the starting motor

is supplied by a 12-volt battery. When the starter and

ignition switch is turned to START, the starter relay is

energized, provided the direction control lever is in

neutral so that the neutral start switch is closed. The

starter relay closes the circuit that energizes the starter

solenoid. The starter solenoid then completes a circuit

from the battery to the starting motor to crank the

engine. When the engine is running, it turns the

the instrument panel indicates the rate of charge. The

headlight and taillight are operated by the light switch

mounted on the instrument panel. The stoplight is

operated by a pressure switch mounted on the brake

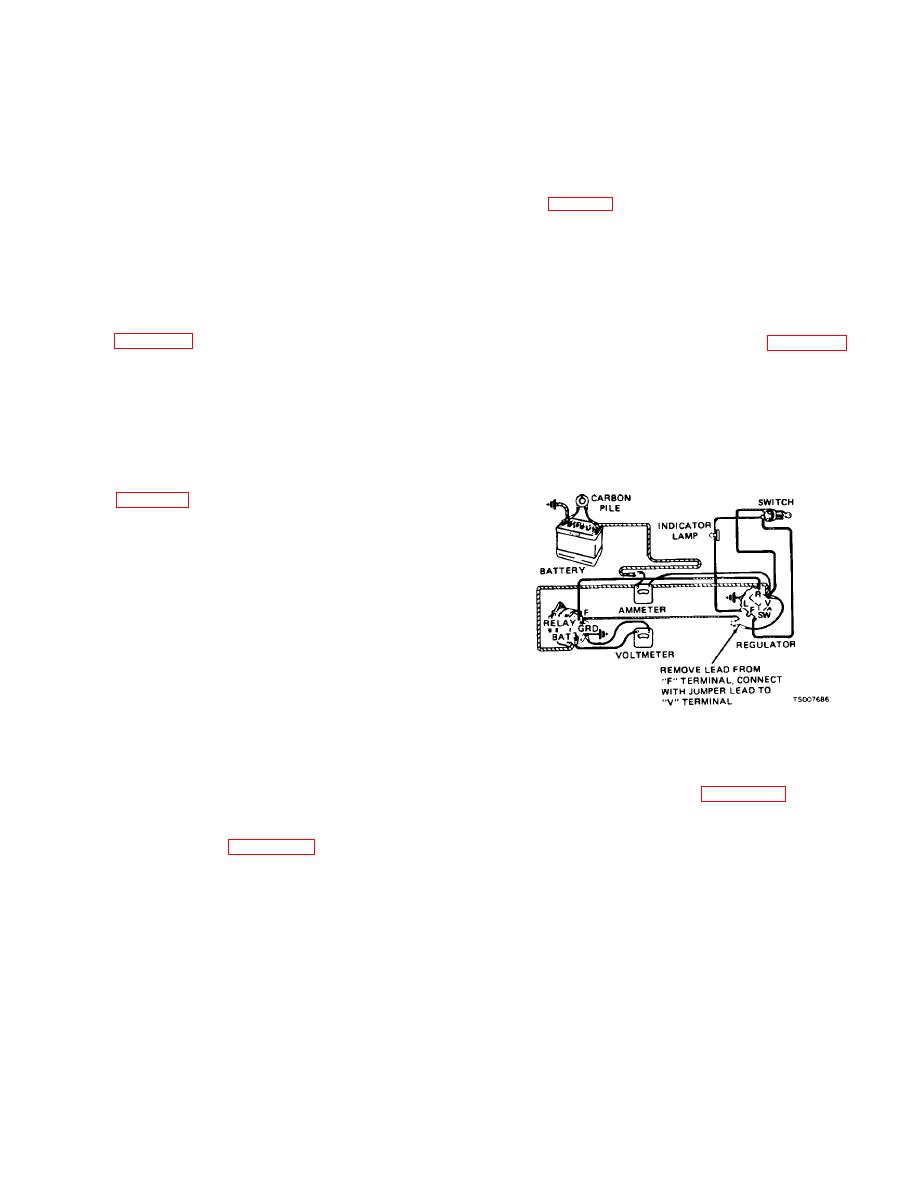

Figure 4-13. Alternator Output Test Setup

master cylinder. This circuit closes only when the

starter and ignition switch is in the run position.

(2) To check operation of field relay, make

4-31. Alternator

meter connections as shown in figure 4-14, connecting

a. Test.

the voltmeter from field terminal of regulator to ground.

Turn on ignition switch, but do not start engine. The

(1) To test alternator output, make meter

voltmeter should indicate battery voltage.

If the

connections as shown in figure 4-13. The carbon pile

voltmeter indicates zero, the field relay is defective.

rheostat across the battery terminals provides an

artificial load for the alternator to work against. Run

engine up to governed speed and check alternator

output. Output should be: 8 Amps @ 80F.-500 Engine

RPM; 31 Amps @ 80F.-2200 Engine RPM.

Change 1 4-29

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |