|

|||

|

|

|||

|

Page Title:

Section XII. HYDRAULIC LIFT COMPONENTS |

|

||

| ||||||||||

|

|

TM 10-3930-632-12

disassembly. If any tags were destroyed, refer to the

overheating, damaged threads, and other damage;

replace damaged switches.

wiring diagram (fig. 1-3} to determine the connection

requirements.

(5)

Inspect the instrument panels for

cracks, dents, distortion, and other damage; replace

(3) Install the instrument panel as shown in

damaged instrument panels.

d. Testing. Proper operation and function of

c. Reassembly and Installation.

the gages can be tested by running the truck engine and

(1) Reassemble the instrument panel as

observing all gages. Check the fuel gage, ammeter, oil

shown in figure 4-5.

gage, and temperature gage for proper readings.

(2) Connect the electrical leads following

the instructions on the tags that were installed at

Section XII. HYDRAULIC LIFT COMPONENTS

4-23. General

The hydraulic lift system consists of a hydraulic pump,

oil reservoir, control valve, lift cylinder, tilt cylinders, and

a tilt-lock valve, together with their connecting hoses

and tubes. Hydraulic oil is drawn from the reservoir by

the pump which is mounted on the engine front cover.

The oil is forced through a high pressure line to the

control valve. When the lift and tilt control levers are in

neutral position, oil flows through the valve and back to

the reservoir. When one of the control levers is

depressed, oil is diverted through tubes and hoses to the

corresponding cylinder and the desired motion is

performed. When the limit of this motion or stroke is

reached (piston rod fully extended or retracted),

pressure built up in the system to approximately 2000

PSI forces a plunger in the relief valve section of the

control valve to open and return excess oil to the

reservoir. The tilt-lock valve prevents the flow of oil to

and from the tilt cylinders when the hydraulic system is

not pressurized even though the control valve lever is

depressed. This prevents tilting of the mast when the

engine is not running.

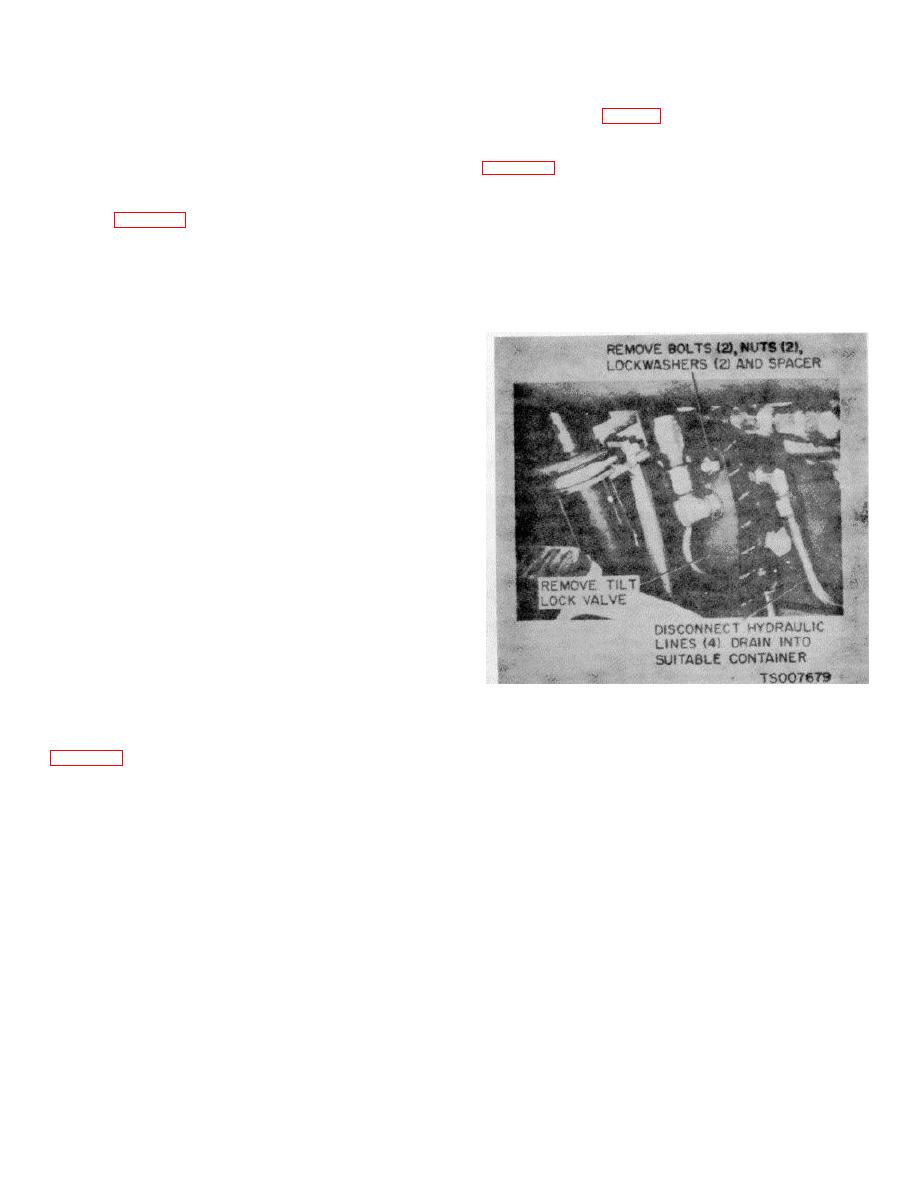

Figure 4-6. Tilt-Lock Valve, Removal and Installation

4-24. Tilt-Lock Valve

a. Removal. Remove the tilt-lock valve as shown in

4-21

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |