|

|||

|

|

|||

|

Page Title:

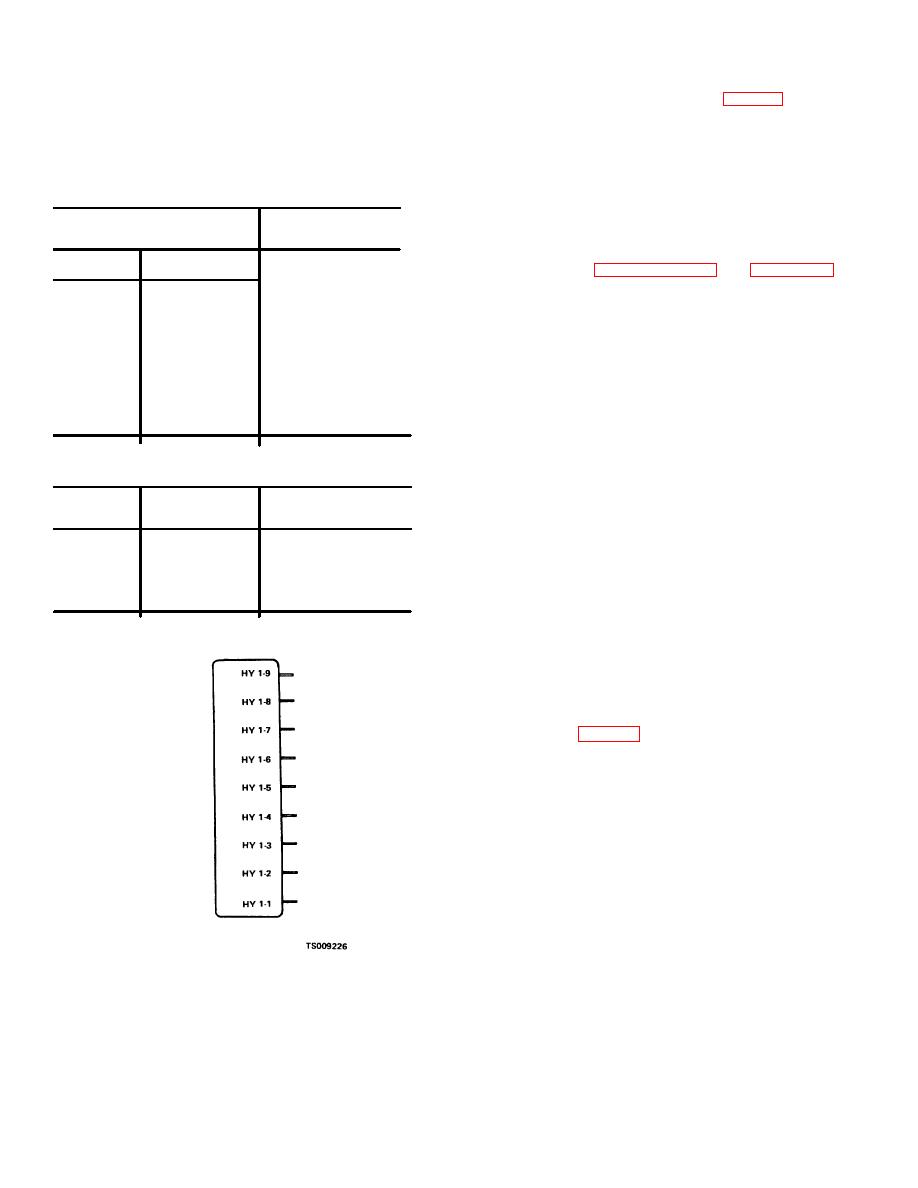

Table 9-1. Diode Suppressor Module Tests |

|

||

| ||||||||||

|

|

TM 10-3930-631-34

left corner of the contactor panel (fig. 2-7). Disconnect

Note

the battery and discharge capacitors. Disconnect the

If any of the readings are not obtained, the diode

wires from the top (anode) of the diodes to isolate them.

suppressor module must be replaced (para. 9-

Connect ohmmeter leads as follows to determine if

24).

diodes are blocking and are in proper polarity.

b. Set the multimeter on the RX1 scale. Touch the

Table 9-1. Diode Suppressor Module Tests

positive lead to the anode and the negative lead to the

cathode. Reading should be low resistance. Touch the

VOM Connection

Reading

positive lead to the cathode and the negative lead to the

(RX1 scale)

anode. Reading should be infinity.

c. Refer to paragraph 9-14 and figure 9-9 and

Positive lead

Negative lead

check diode for blocking capability.

9-19. Positive Temperature Coefficient Resistor

HY1-3

HY1-5

Low resistance

HY1-5

HY1-3

High resistance

Test

HY1-7

HY1-8

Low resistance

a. The positive temperature coefficient resistor is

HY1-8

HY1-7

High resistance

mounted on the heatsink at the end of the static panel. It

HY1-7

HY1-6

Low resistance

is a temperature sensitive device which increases in

HY1-6

HY1-7

High resistance

resistance with an increase in tem- perature. As the

HY1-4

HY1-9

45-120 ohms

temperature of the heatsink increases, the resistance of

HY1-9

HY1-4

High resistance

the resistor increases. Since the resistor is wired into the

circuit of the control module, this increased resistance

VOM Connection

Reading

decreases the speed of the lift truck. The lift truck will

(RX1 scale)

operate at a reduced speed until the heatsink

temperature drops to a normal value; then once again

Positive lead

Negative lead

full speed is available.

b. Disconnect yellow wires from the resistor and

HY1-1

HY1-2

20K to infinity

connect a VOM set on RX1 scale to the resistor

HY1-2

HY1-1

20K to infinity

terminals (PR1 and PR2). Reading should be less than

HY1-3

HY1-4

20K to infinity

200 ohms if heatsink is at room temperature

HY1-4

HY1-3

20K to infinity

(approximately 700F (21 C). Set VOM on highest ohms

scale and check each terminal to heatsink resistance;

both readings should be infinity.

9-20. Capacitors

a. One method of checking C1 thru C5 capacitors

to determine if they are good is as follows:

b. Connect a fully charged test battery or lift truck

battery, a 10K ohm resistor in series, and a voltmeter to

the capacitor (fig. 9-11), but do not connect the negative

lead to the battery. Use a watch with a sweep second

hand to time the period of charging. Now connect the

negative lead to the battery and begin timing. After 37

seconds, the capacitor voltage should be approximately

22 volts ( 4 volts).

Figure 9-10.Diode suppressor module.

9-18. D3 and D4 Diode Test

a. D3 and D4 diodes are located at the upper

9-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |