|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-631-34

b. Disconnect the cable which connects the B +

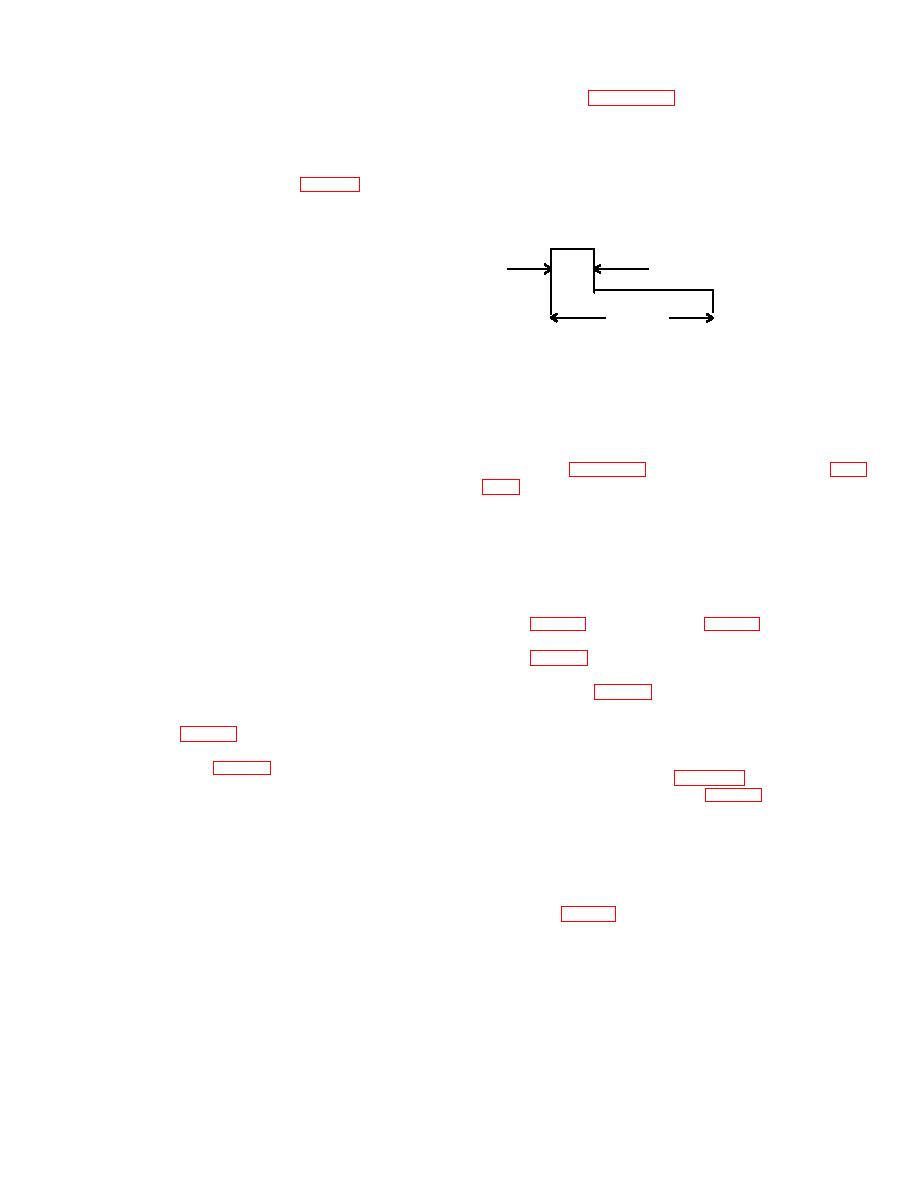

as shown on figure 9-7. The pulse width should

stud and free wheeling diode cathode to B + of the

increase with increased pedal depression.

The

capacitors from the capacitors.

maximum on time will be approximately 33 percent.

c. Utilize a multimeter to make this check:

VERTICAL 1V/CM

(1) Use the high ohms scale on multimeter.

HORIZONTAL 1MS/CM

Touch positive lead to diode block (fig. 9-6) or power

switch module frame and negative lead to B- stud.

FREQUENCY WILL BE APPROXIMATELY 275 TO

Reading should be greater than 50K ohms.

350 HERTZ

(2) Use low ohms scale. Touch positive lead to

5V

B-- stud and negative to diode block or power switch

module. Reading should be less than 100 ohms.

d. If the above readings are not obtained the

power switch modules are open, one or more are

3.3

SEC

shorted or the control board is defective. Replace

TS009223

components as necessary.

Figure 9-7. Waveform for control board output.

e. The following checks may be used to determine

the problem:

c. If the above conditions do not occur, check as

(1) To determine which power switch module is

follows.

shorted remove the bus bar mounting cap- screws and

(1) Contactors do not energize.

insulate the B- bus bar from the power switch modules.

(a) Faulty wiring-check continuity.

Perform the VOM check above and if the faulty condition

(b) Shorted diode suppressor module. Check

remains proceed to following step (2). If the shorted

the module (para. 9-17), and replace if necessary (para

condition no longer exists connect B- with a jumper wire

to each B- connection on the power switch module and

(c) Improperly adjusted or faulty speed

repeat the above VOM check until the faulty module is

potentiometer. Adjust or replace if necessary. (para 9-

found. Replace the shorted module and repeat the

12).

VOM check.

(2) No buzzing from regulators.

If the

(2) Disconnect the orange wire from the A2

contactors, energize and no audible buzzing is heard

terminal. Repeat the VOM test. If the test is satisfactory

from the drive regulators, check the continuity from the F

replace the control circuit module and repeat the VOM

or R contactor contacts thru fuses F3 to F4, diodes D3

test.

to D4 (fig. 2-8), and resistor R1 (fig. 2-8) to control plug

Note

pin P2-11. Check from P2-11 to the B + input (white/red

Connect all wires and cables before continuing

wire) (fig. 9-6) on the drive regulator modules. If the

with further tests.

fuses were blown, check diodes D3 and D4 on the

9-8. Control Board Output Test

contactor panel (fig. 2-8) and capacitor C3 on the static

Note

panel for shorts. The drive regulator may be defective.

The control board is a component of the control

Replace as necessary.

circuit module (fig. 9-6).

(3) Waveform is not as indicated.

a. Connect the positive lead of an oscilloscope to

(a) Defective positive temperature coefficient

the white wire lead S1 (fig. 9-6) on the drive regulator.

resistor. Check the resistor (para 9-19).

Connect the negative lead of the oscilloscope to B--.

(b) Undervoltage switch (fig. 9-6) on the control

(1) Connect battery.

board is in the incorrect position. Place in correct

(2) Sit on the operator's seat.

position. (36 volts).

(3) Turn the key switch to ON.

(c) Defective

wiring

harness

or

poor

(4) Put the forward and reverse lever into a

connections on the static panel. Check and repair or

direction.

replace defective connections or harness.

(5) Depress the accelerator pedal slightly to

(d) Defective control board. Disconnect the

energize the contactor.

white wire (fig. 9-6) from the S1 terminal of the #1 drive

b. The contactor should energize after a small

regulator. Connect the positive lead of the scope to the

amount of pedal depression. As soon as the contactor

white wire and observe the

energizes an audible buzzing should be heard from the

drive current regulators. The waveform observed on the

oscilloscope should be

9-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |