|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-631-34

(4) Clean brushes, holders and wipe com-

(11)Attach a loop to pressure end of coil spring

mutator with a dry, lint-free cloth.

and connect a spring scale to loop. Pull on scale and

(5) Check appearance of commutator and brush

check spring pressure reading. Total spring pressure

contact surfaces. Signs of good commutation are a dark

should be 40 ounces (1.08 kg). Replace spring if

brownish highly polished commutator and uniform glossy

pressure does not reach this amount.

brush contact surfaces.

(12)Remove spring scale. Install rear cover on

(6) Check brush wires for good contact with

drive motor.

brush holder. Wires must not be damaged or burned.

(13)Install drip pan and floor and toe plates.

b. Removal.

(7) Check brush length. Replace brushes when

metal clips on brushes clear the bottom of the holder

(1) Disconnect battery receptacle and discharge

indent by less than 0.125 inch (3.175 mm).

capacitors. Lift front of truck high enough to gain access

(8) Before installing new brushes, contour brush

to drive motor. Block in position. Remove floor and toe

contact surfaces on a sanding drum the same diameter

plates and drip pan.

as commutator. Hold brushes on drum to obtain same

(2) Tag and disconnect drive motor cables.

radius and brush angle on contact surface as old

Disconnect wires from thermal relay attached to drive

brushes. Clean brushes after sanding.

motor. Remove screws and remove thermal relay from

(9) Install brushes by lifting end of brush spring

motor housing.

(3) Refer to paragraph 4-2 and disconnect pin

brush spring for good contact with brush flange.

from parking brake actuating lever and remove brake

Connect brush wires to brush holder.

calipers, bracket and brake disk from drive motor.

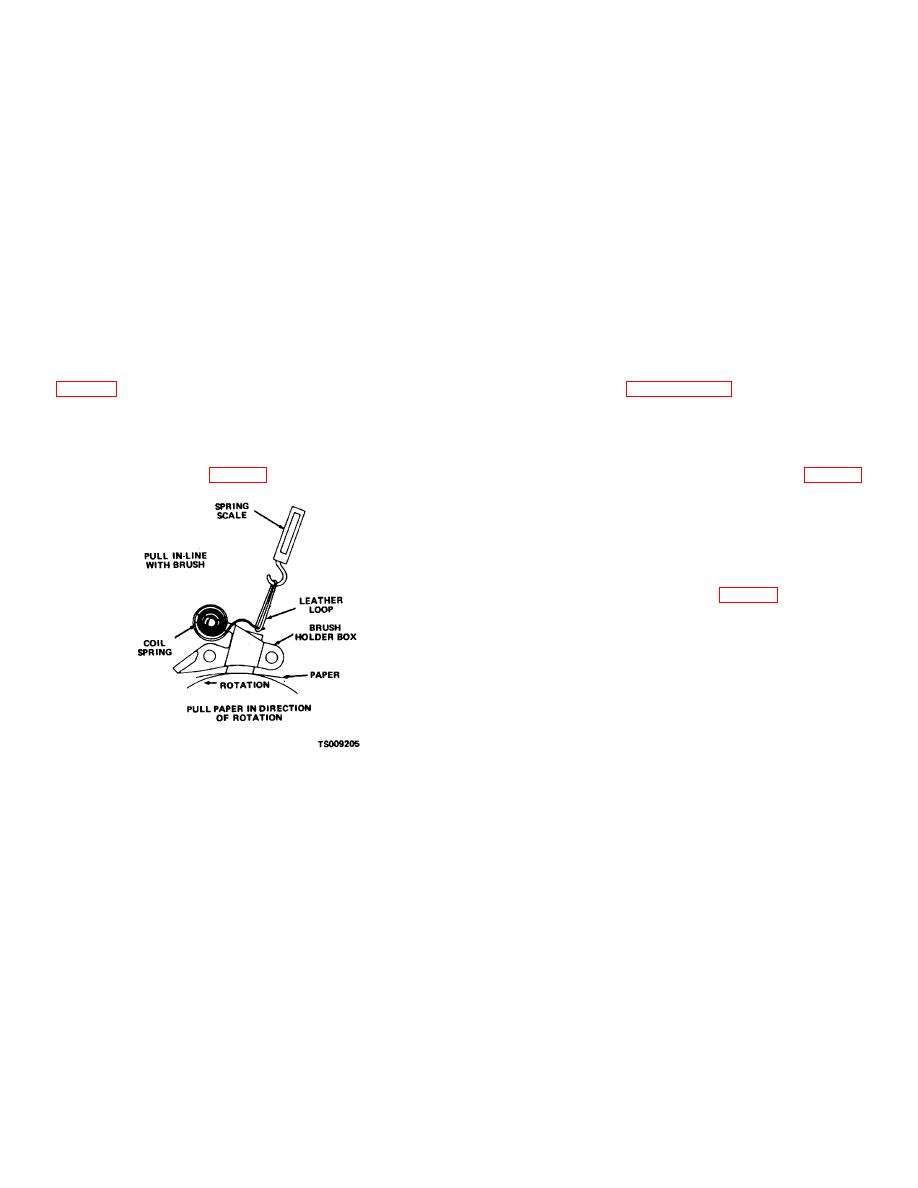

(10)Check brush spring for proper pressure.

(4) Place a jack or other suitable support under

Install thin strong paper between brush and contact

drive motor and raise enough to support motor. Drain oil

surface of commutator (fig. 8-2).

from differential carrier. (5) Remove screws (5, fig. 3-8)

and lock washers (6) and remove drive motor from

differential carrier. Remove gasket (9).

c. Disassembly.

(1) Clean exterior of motor with cleaning

compound, solvent (Fed. Spec. P-D-680) and dry

thoroughly.

(2) Remove rear cover (2, fig. 8-3) and remove

brushes (a. above) from motor.

Figure 8-2. Checking brush spring pressure.

8-2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |